Creating an Evisceration Performance Measurement Framework for Enhanced Food Safety Standards

តុលា . 08, 2024 15:39 Back to list

Creating an Evisceration Performance Measurement Framework for Enhanced Food Safety Standards

Understanding the Evisceration Table A Key Element in Food Safety and Quality Control

In the contemporary food industry, maintaining high standards of food safety and quality is paramount. One critical aspect of this process is the evisceration procedure, particularly in the processing of poultry and certain other meats. The evisceration table plays an essential role in this process, serving as both a functional workspace and a crucial component in ensuring that food products meet regulatory standards and consumer expectations.

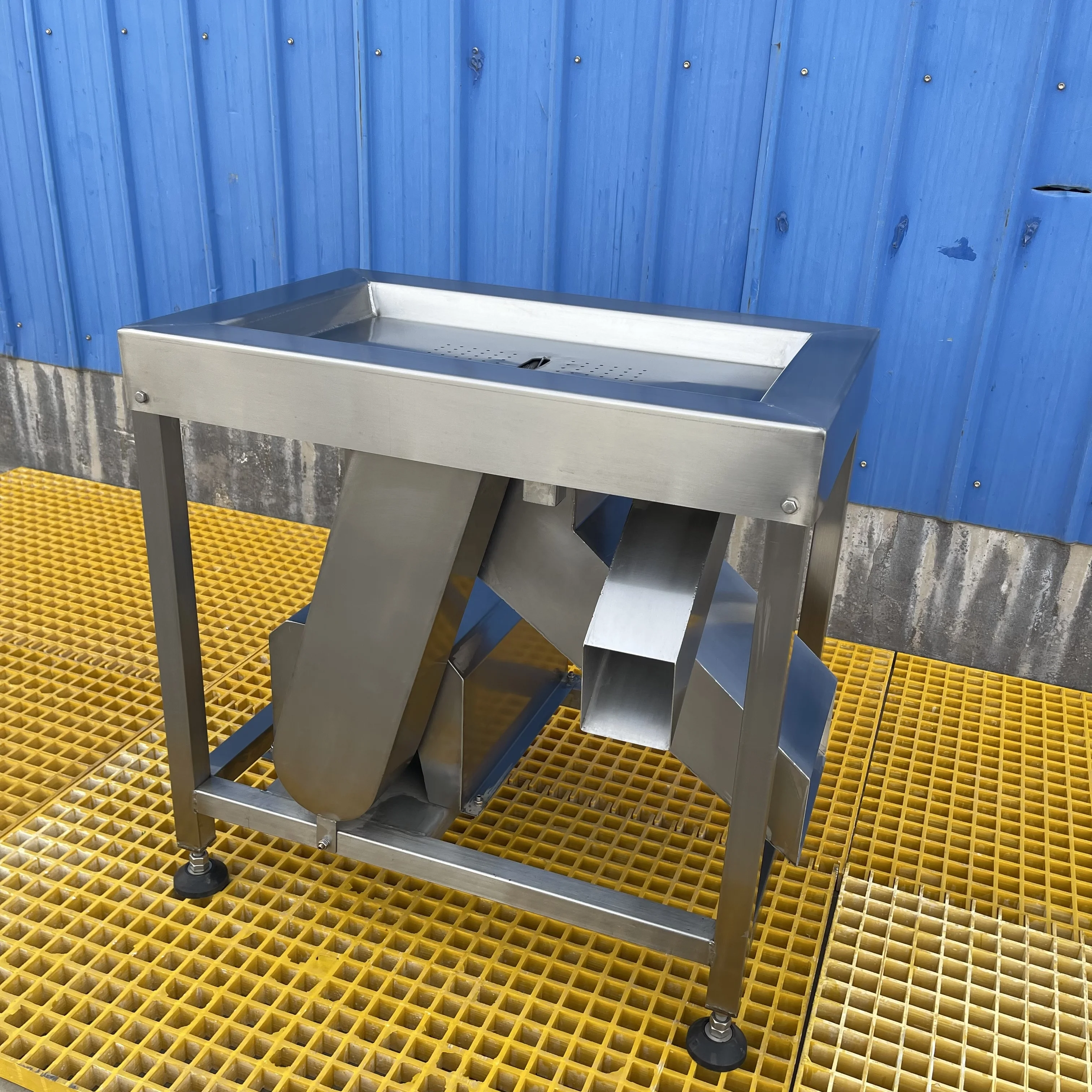

Evisceration refers to the removal of internal organs from animals post-slaughter, which is a necessary step to prepare the meat for further processing, packaging, and distribution. The evisceration table is specifically designed to facilitate this process by providing a designated area where workers can safely and efficiently perform the removal of entrails while minimizing the risk of contamination.

The design of an evisceration table is rooted in ergonomic principles, ensuring that workers can carry out their tasks comfortably and efficiently

. Typically made from stainless steel, these tables are built to withstand rigorous cleaning protocols while preventing the growth of bacteria, which is vital in maintaining hygiene. Additionally, the surface is often sloped to allow easy drainage of water and byproducts, further enhancing sanitation practices during the evisceration process.evisceration table

One of the primary concerns during evisceration is the prevention of cross-contamination. The evisceration table is strategically located in a workflow that minimizes the chances of contact between raw and cooked products. This positioning is crucial in larger processing facilities where multiple stages of meat preparation occur. The practice of maintaining a clean workspace is an industry standard, and regular cleaning schedules are implemented to ensure that the evisceration table remains free from contaminants.

Moreover, the evisceration process requires that workers are adequately trained in handling meat safely and efficiently. Training encompasses understanding the anatomy of the animals being processed, recognizing signs of spoilage or disease, and following best practices for hygiene. A well-trained workforce is essential in maintaining the quality of the meat and ensuring the safety of the food supply.

The evisceration table is also instrumental in data collection and quality control measures. Many facilities employ a monitoring system that tracks various aspects of the evisceration process, including time taken for each operation, the number of products being processed, and any anomalies that may occur. Such data is invaluable in optimizing processes, responding to quality concerns, and improving overall efficiency.

In summary, the evisceration table serves as a cornerstone in the meat processing industry, linking food safety, quality control, and ergonomic efficiency. Its design and operational procedures contribute significantly to reducing contamination risks and ensuring that meat products meet the safety standards required by regulatory bodies. As the industry continues to evolve, the importance of such specialized equipment in facilitating safe and efficient food processing cannot be overstated. By understanding the role of the evisceration table, stakeholders in the food industry can appreciate the meticulous efforts that go into delivering safe and high-quality meat products to consumers.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025