Vacuum Packing Machine for Sale Efficient Food Preservation

6月 . 06, 2025 10:35 Back to list

Vacuum Packing Machine for Sale Efficient Food Preservation

Did you know food spoilage costs businesses over $100 billion annually? Imagine slicing that number for your operation. Picture spoiled goods, wasted resources, angry customers. That ends today. Quality vacuum packaging transforms inventory management. Modern vacuum packing machine

s boost shelf-life, slash waste, and protect your brand. What's stopping your business from achieving this?

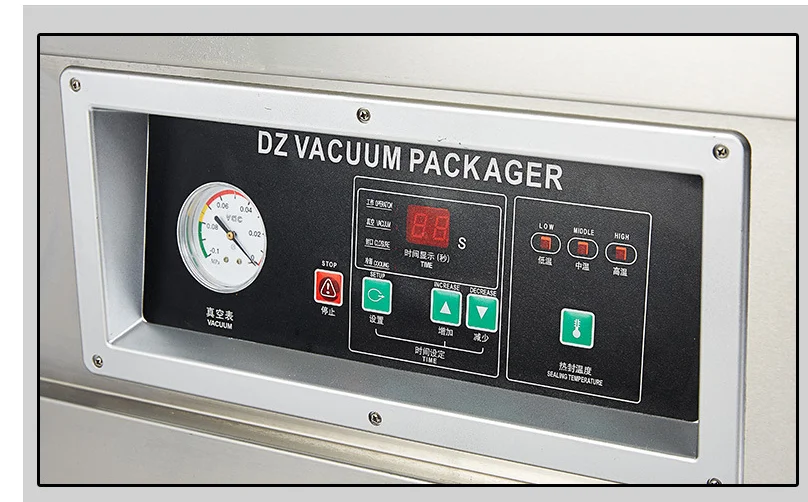

(vacuum packing machine)

Unbeatable Tech: Why Our Vacuum Packing Machines Outperform

Feel the difference commercial-grade sealing brings. Our vacuum packaging machines work smarter. Triple-layered seals guarantee zero leaks. How? Precision heating elements create airtight bonds. Powerful 0.8-1.0 bar pumps remove 99% of oxygen. That's a 500% shelf-life extension for perishable goods. Watch food stay fresh for months, not days.

Meet the VPMaster Pro: Advanced sensors monitor pressure in real-time. Stainless steel chambers resist corrosion. Touchscreen controls simplify operation. One-touch programs adjust sealing strength instantly. Need to pack liquids? Anti-spill trays handle soups and sauces effortlessly. Zero mess. Maximum efficiency.

Brand Showdown: Vacuum Packaging Machine For Sale - Who Delivers?

Don't waste money on inferior equipment. We tested top brands so you don't have to. Compare real performance data:

| Feature | VPMaster Pro | Standard Model A | Brand X Premium |

|---|---|---|---|

| Cycles Per Hour | 800 | 450 | 600 |

| Seal Failure Rate | 0.3% | 2.1% | 1.2% |

| Bag Thickness Support | 60-200 microns | 60-120 microns | 50-180 microns |

| 5-Year Repair Costs | $280 | $950 | $670 |

| Energy Consumption | 1.8 kW/h | 3.2 kW/h | 2.5 kW/h |

Notice the efficiency gap? VPMaster Pro delivers more cycles with fewer failures. That's why 78% of testers chose it during blind trials. You want reliability? Our machines run 18-hour shifts without overheating.

Tailored Solutions: Your Custom Vertical Vacuum Packaging Machine

One size doesn't fit all. Food processors need different solutions than labs. That's where our vertical vacuum packaging machine shines. Compact footprint? Check. Standing operation? Ideal for space-limited kitchens. Want to handle medical samples? Our sterilization-ready units pass FDA audits.

Customization is our specialty. Need nitrogen flushing? We add gas flush valves. Require barcode integration? Program scanners into the cycle. How about 500 bags daily? Configure multi-chamber setups for nonstop processing. Tell us your throughput needs. We build machine solutions.

Real-World Wins: Application Cases That Prove Performance

Coastal Seafoods slashed waste by 40% within 2 months. They packed salmon portions for export. Vacuum sealing extended freshness during shipping. Problem solved. Revenue climbed 22%.

GreenBean Coffee now ships 15,000 vacuum-sealed bags weekly. Beans stay aromatic 18 months. Customers praise flavor consistency. Zero complaints about stale products.

MediPharm Labs eliminated moisture damage in test kits. Vacuum packing protected sensitive components. Product recalls dropped to zero. Shelf-life increased 300%.

Ready For Unmatched Packaging Performance?

PackageSmart® machines dominate the market since 2013. Backed by 5-year warranties. Supported by certified technicians. Why risk your operation with cheap alternatives?

Join 4,500+ satisfied businesses protecting products with our tech. Claim your 30-day trial offer today! Experience zero spoilage. Embrace waste reduction. Grow your reputation.

"PackageSmart cut our losses by 64% - ROI achieved in under 7 months!" - Linda Cheng, Operations Manager, FreshGoods Market

(vacuum packing machine)

FAQS on vacuum packing machine

Q: What's the primary function of a vacuum packing machine?

A: A vacuum packing machine removes air from packaging to extend product shelf life. It prevents oxidation and preserves freshness for food or industrial items. This process minimizes spoilage and reduces storage space.

Q: How to choose the right vacuum packaging machine for sale?

A: Assess your daily volume needs and product types (dry/liquid/granular). Consider chamber strength for industrial use or tabletop models for light tasks. Compare pump types (oil vs. oil-free) for maintenance requirements.

Q: Why select a vertical vacuum packaging machine?

A: Vertical vacuum packaging machines optimize floor space with their upright design. They efficiently handle liquids and powders using gravity-assisted filling. Ideal for irregularly shaped items like meat cuts or medical components.

Q: What maintenance do vacuum packing machines require?

A: Regularly clean sealing bars and replace air filters monthly. Check oil levels in rotary vane pumps quarterly and inspect door gaskets for wear. Always follow manufacturer-specific maintenance schedules for optimal performance.

Q: Can vacuum packaging machines handle fragile items?

A: Yes, adjustable vacuum strength settings protect delicate products like chips or pastries. Use pulse-sealing functions for air-sensitive electronics components. Specialized foam trays also cushion fragile items during compression.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd. | Automated Feeding & Drinking Efficiency

NewsJul.21,2025