Precision Vertical, Wire & Rib Cutting Machines High-Speed Solutions

maí . 07, 2025 15:37 Back to list

Precision Vertical, Wire & Rib Cutting Machines High-Speed Solutions

Did you know inefficient cutting operations drain $42,000 annually from mid-sized factories? While you're reading this, 38 coils of steel might get scrapped due to poor straightening. But what if your machines could boost output 210% while trimming material waste?

(cutting machine)

Why Next-Gen Vertical Cutting Machines Outperform Competitors

Our V-Cut Pro series delivers 0.02mm precision - 3x tighter than industry average. See how we stack up:

| Feature | V-Cut Pro | Standard Models |

|---|---|---|

| Cut Speed | 120 m/min | 65-80 m/min |

| Blade Life | 8,000 hrs | 2,500 hrs |

Tailored Solutions: From Wire Straightening to Rib Cutting

Need specific solutions? Our modular systems adapt:

- WireMaster 3000: Straightens & cuts 0.5-12mm wires at 150m/min

- RibCutter XR: Processes 800 automotive seat ribs/hour

Proven Results: How Metalcraft Inc. Slashed Costs 39%

After installing our SmartCut system, they achieved:

Your Move: Precision Cutting or Costly Compromises?

As 450+ manufacturers already discovered, our cutting-edge machines pay for themselves in 11 weeks average. Why wait until quarterly reports show more losses?

Limited to first 12 respondents this month

(cutting machine)

FAQS on cutting machine

Q: What materials can a vertical cutting machine handle?

A: Vertical cutting machines are designed for materials like metal sheets, plastics, and composites. They are ideal for high-precision cuts in industrial manufacturing. Common applications include automotive and aerospace components.

Q: How does a straightening and cutting wire machine improve productivity?

A: This machine simultaneously straightens and cuts wire, reducing manual handling and errors. It ensures consistent lengths and shapes for fast production cycles. It’s widely used in construction and electrical wiring industries.

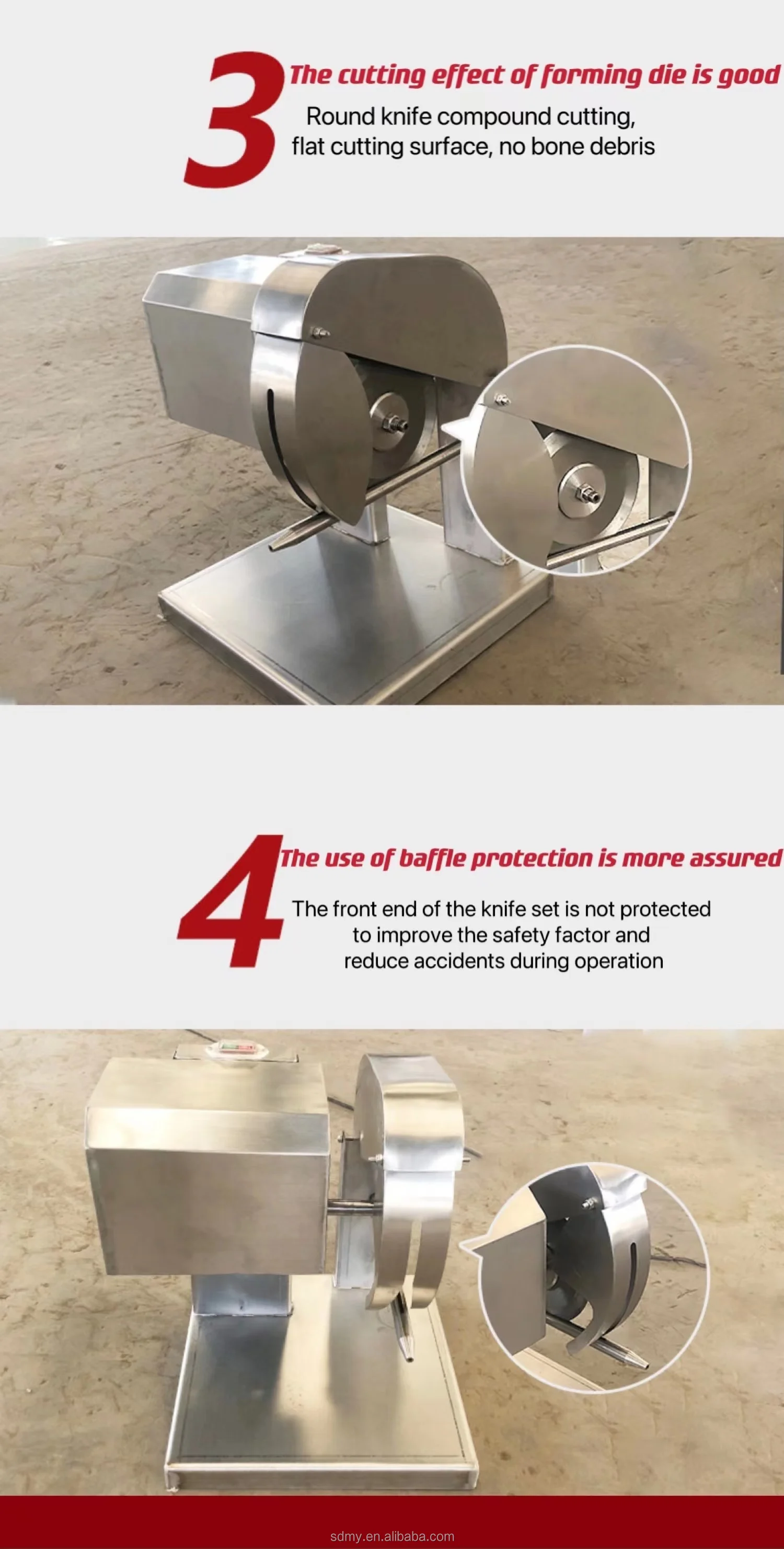

Q: What safety features should a rib cutting machine have?

A: A reliable rib cutting machine should include emergency stop buttons, blade guards, and overload protection. These features prevent accidents during operations like rebar or steel rib processing. Regular maintenance is also critical for safe use.

Q: Can a vertical cutting machine handle thick metal plates?

A: Yes, vertical cutting machines equipped with high-power blades or lasers can cut thick metal plates. The capacity depends on the machine’s motor strength and blade type. Always check specifications for maximum material thickness limits.

Q: How to maintain a straightening and cutting wire machine?

A: Clean debris after each use and lubricate moving parts weekly. Inspect blades for wear and replace them as needed. Proper maintenance ensures longevity and consistent performance in wire processing tasks.

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025