automatic egg tray making machine

des . 04, 2024 10:08 Back to list

automatic egg tray making machine

Understanding Automatic Egg Tray Making Machines Revolutionizing Sustainable Packaging

In recent years, the growing concern for environmental sustainability has propelled innovations in various sectors, including packaging. One notable advancement in this field is the automatic egg tray making machine. This technology not only addresses packaging needs but also promotes recycling and waste management, making it an essential tool for businesses aiming to minimize their carbon footprint.

What is an Automatic Egg Tray Making Machine?

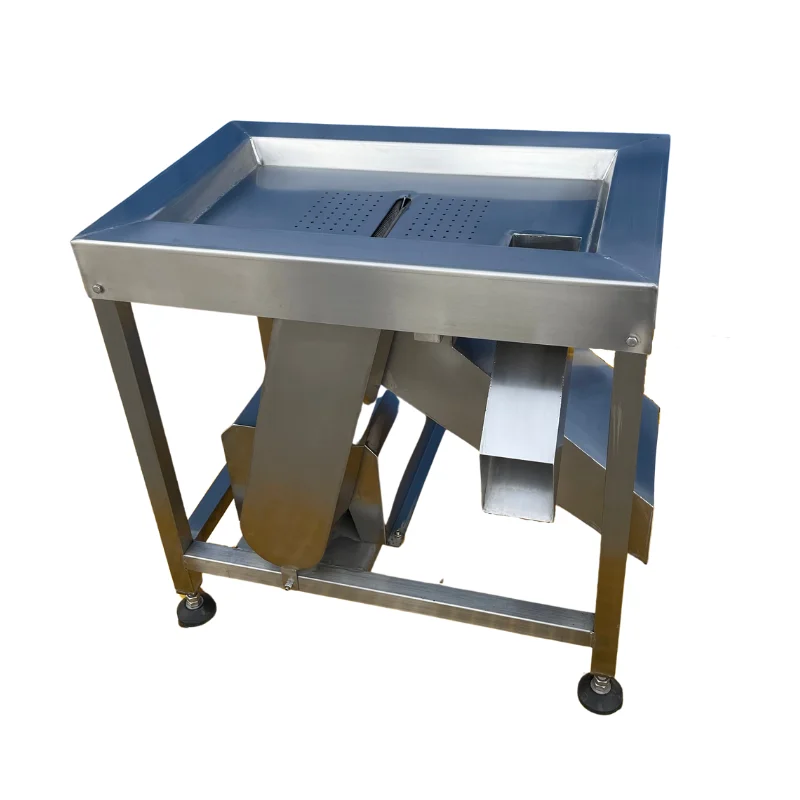

An automatic egg tray making machine is a specialized equipment designed to produce egg trays efficiently and in large quantities. These machines utilize waste paper, cardboard, or other cellulosic materials as raw materials, which are pulped to create a slurry. This slurry is then molded into egg trays using a series of automated processes, including forming, drying, and pressing. The result is a robust and lightweight product that provides excellent protection for eggs during transportation and storage.

Key Features and Advantages

One of the standout features of automatic egg tray making machines is their automation. Unlike manual processes, which are labor-intensive and time-consuming, these machines automate various stages of production, leading to higher efficiency and consistency in quality. Some of the critical advantages include

1. High Production Capacity Automatic machines can produce thousands of egg trays per hour, catering to the demands of large-scale poultry farms and distribution companies. 2. Cost-Effectiveness By streamlining the production process, businesses can significantly reduce labor costs and increase their profit margins. The use of recycled materials also contributes to lower raw material costs.

3. Eco-Friendly Solution The reliance on recycled paper and the machine's ability to turn waste into product mean a reduction in landfill waste. This aligns with global efforts to promote sustainable practices and reduce plastic usage.

4. Durability and Protection Egg trays made from high-quality pulp are sturdy and designed to protect the eggs from damage. Their design minimizes movement, thus reducing the risk of breakage during transit.

5. Customizable Designs Many manufacturers offer options for customization, allowing businesses to create egg trays that fit specific sizes or to incorporate branding elements.

The Production Process

automatic egg tray making machine

The operation of an automatic egg tray making machine typically follows several key steps

1. Pulping Waste paper or other fibrous materials are collected and processed into a slurry through water and mechanical action. This step is crucial as it determines the quality of the final product.

2. Molding The pulp slurry is poured into molds shaped like the egg tray. A vacuum suction system helps in forming the tray while removing excess water.

3. Drying The molded trays are placed in a drying system, which can utilize hot air or sunlight, depending on the design of the machine. This process hardens the trays and prepares them for packaging.

4. Pressing Some machines incorporate a pressing phase to ensure that the trays are compact and uniform in shape. This step can also improve the trays’ structural integrity.

5. Stacking and Packaging Finally, dried trays are stacked and packaged for shipment to retailers or directly to customers.

Market Trends and Future Outlook

With the increasing demand for sustainable packaging solutions, the market for automatic egg tray making machines is experiencing significant growth. Poultry businesses are increasingly recognizing the benefits of using eco-friendly packaging, which in turn drives the demand for these machines. Furthermore, advancements in technology, including the integration of smart systems and IoT, are expected to make these machines even more efficient and user-friendly.

As consumers become more environmentally conscious, businesses that adopt sustainable practices will likely gain a competitive edge. The automatic egg tray making machine is at the forefront of this transition, providing an innovative and responsible solution to packaging challenges.

Conclusion

In summary, the automatic egg tray making machine plays a pivotal role in revolutionizing how businesses approach packaging, particularly in the food industry. By producing durable, eco-friendly trays from recycled materials, it not only enhances operational efficiency but also aligns with global sustainability initiatives. As technology continues to advance, these machines will undoubtedly evolve, further solidifying their importance in the quest for sustainable development. For any business involved in poultry and egg distribution, investing in such technology is not merely an option but a step towards a greener future.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025