Feed Pellet Cooler Rapid Cooling & Energy-Efficient Solutions

Mei . 11, 2025 10:19 Back to list

Feed Pellet Cooler Rapid Cooling & Energy-Efficient Solutions

Did you know 68% of feed manufacturers lose product quality due to improper cooling? When your pellets exit the dryer at 80-90°C, every minute of delayed cooling risks microbial growth and nutrient loss. This is where feed pellet cooler

s become your production line's superhero.

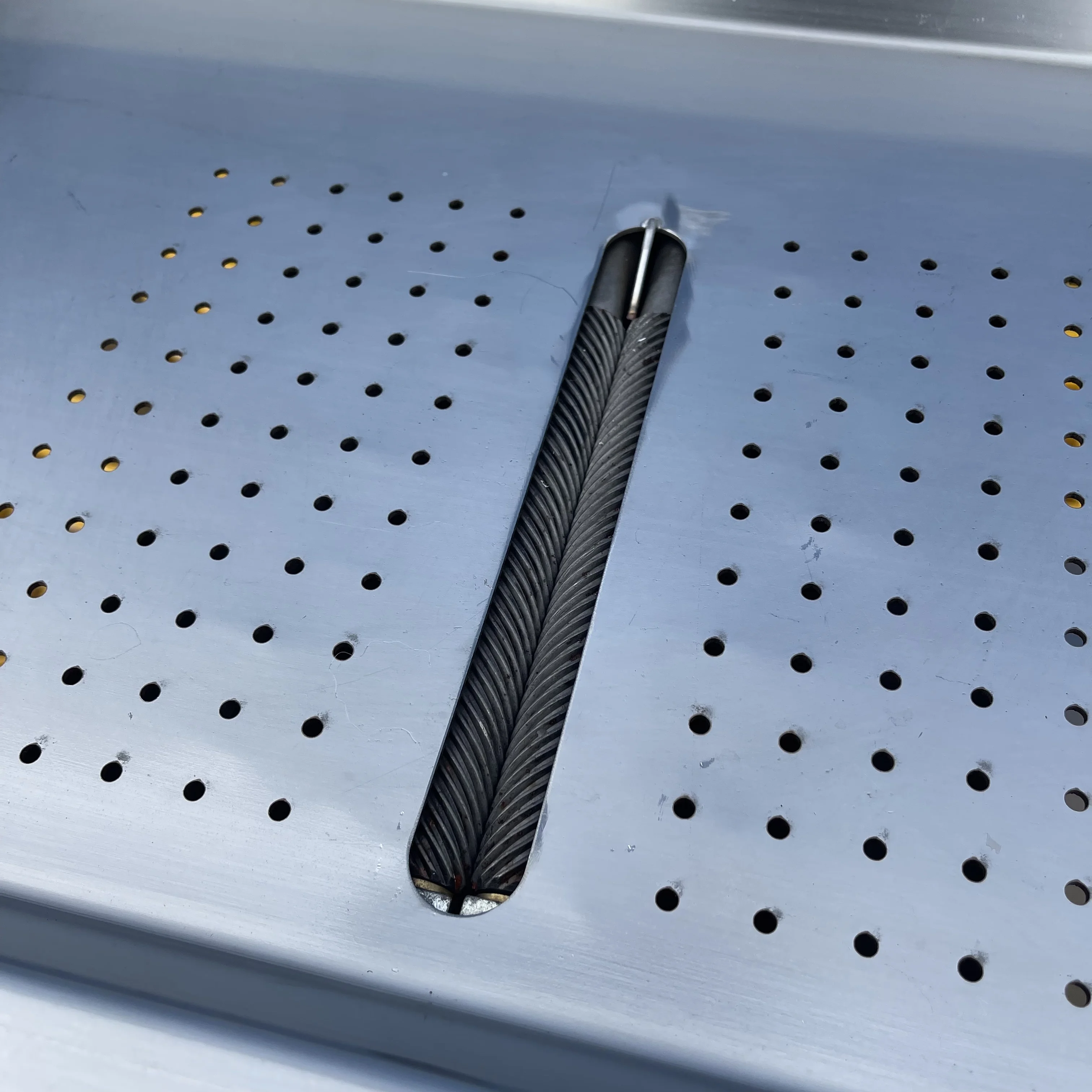

(feed pellet cooler)

Technical Superiority That Makes Competitors Sweat

Our ultra cool evaporative cooler pads achieve 40% faster temperature drop than conventional models. How? Through three breakthrough innovations:

- ✓ Hexagonal cellulose matrix

- ✓ 360° airflow distribution

- ✓ Anti-clogging nano-coating

| Feature | Standard Models | Our Tech |

|---|---|---|

| Cooling Cycle Time | 25-30 mins | 12-15 mins |

Why 300+ Factories Choose Our Cooling Systems

When comparing cooling pad for evaporative cooler solutions, three factors decide victory:

Energy Efficiency

35% lower power consumption than industry average

Maintenance Cost

Self-cleaning system saves $12,000/year

Ready to Boost Your Production Quality?

Claim your FREE cooling efficiency audit this month and discover how much you could save!

(feed pellet cooler)

FAQS on feed pellet cooler

Q: How does a feed pellet cooler work to reduce temperature after processing?

A: A feed pellet cooler uses ambient air or forced ventilation to dissipate heat and moisture from freshly processed pellets. This stabilizes pellet quality and prevents mold growth. The process typically involves a rotating drum or vertical column with airflow systems.

Q: What are the benefits of ultra cool evaporative cooler pads in pellet cooling systems?

A: Ultra cool evaporative cooler pads enhance cooling efficiency by lowering air temperature through water evaporation. They reduce energy consumption compared to mechanical cooling and maintain optimal moisture levels for feed pellet integrity. These pads are ideal for high-temperature environments.

Q: How often should cooling pads for evaporative coolers be replaced in feed pellet production?

A: Cooling pads typically require replacement every 6-12 months, depending on water quality and usage frequency. Regular cleaning prevents mineral buildup and algae growth. Inspect pads monthly for wear or clogging to ensure consistent performance.

Q: Can cooling pad materials affect feed pellet quality in evaporative coolers?

A: Yes, low-quality pads may shed fibers or introduce contaminants into pellets. Food-grade cellulose or synthetic pads are recommended to ensure hygiene and airflow consistency. Always select pads designed for agricultural or industrial cooling applications.

Q: Are evaporative cooler pads interchangeable between feed pellet coolers and other systems?

A: While some pads are universal, feed pellet coolers often require heavy-duty pads resistant to organic particles. Check compatibility with airflow rates and thickness (e.g., 4"-6" pads). Custom sizing may be needed for specialized pellet cooling equipment.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd. | Automated Feeding & Drinking Efficiency

NewsJul.21,2025