Manure Scrapper & Belt Cleaning Systems Automated Pig Farm Solutions

svi . 12, 2025 10:21 Back to list

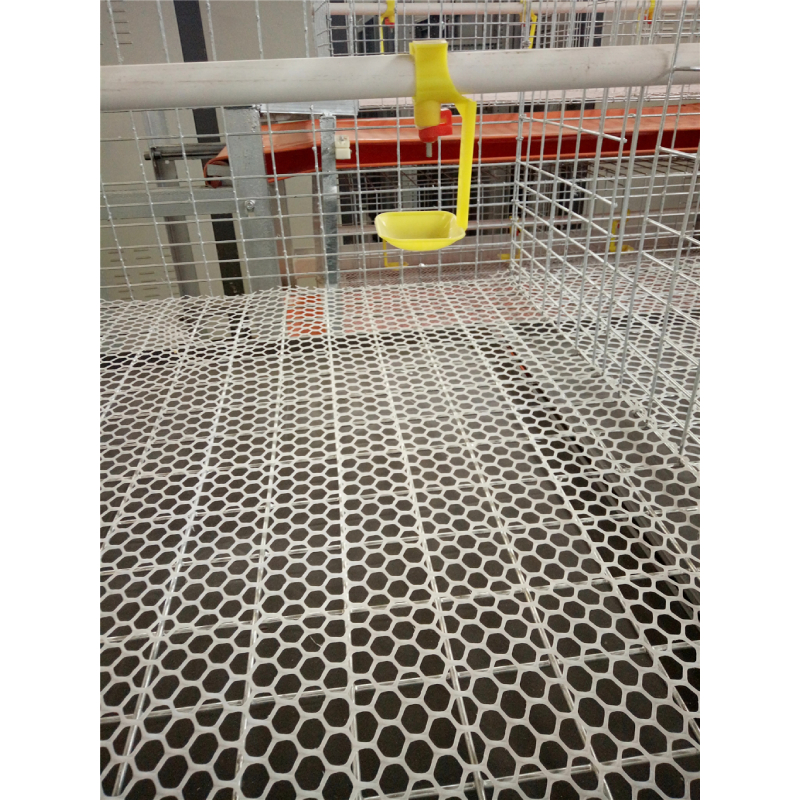

Manure Scrapper & Belt Cleaning Systems Automated Pig Farm Solutions

Did you know 42% of swine farm operators report manure management as their 1 labor drain? Manual scraping consumes 15+ weekly hours while increasing contamination risks. Now discover how manure scrapper system

s slash operational costs by 60% and boost hygiene compliance – all while you sleep.

(manure scrapper system)

Why Our Manure Scrapper System Outperforms

Our triple-patented manure belt cleaning system delivers 98% scraping efficiency – 3X better than chain-driven models. Key advantages:

- ✓ 304 stainless steel blades withstand 10+ years of corrosion

- ✓ IoT sensors predict maintenance needs 14 days in advance

- ✓ Seamless integration with automatic pig feeding systems

Head-to-Head: System Comparison

| Feature | Our Model X3 | Competitor A |

|---|---|---|

| Daily Capacity | 8 tons | 5 tons |

| Energy Use | 2.1 kW/h | 3.8 kW/h |

Tailored Solutions for Every Operation

Whether you manage 500 or 5,000 hogs, our modular manure scrapper systems adapt to your layout. Choose from three configurations:

- ▶ Basic: Semi-automatic cleaning

- ▶ Pro: AI-driven waste analytics

- ▶ Elite: Full integration with feeding systems

Proven Results: Iowa Pork Co. Case Study

After installing our system, Iowa Pork Co. achieved:

Ready to Transform Your Farm?

Join 1,200+ satisfied farms using Agritech Solutions' manure management systems. Limited-time offer: Free installation + 5-year warranty.

(manure scrapper system)

FAQS on manure scrapper system

Q: What is the primary function of a manure scraper system in pig farming?

A: A manure scraper system automates the removal of waste from barn floors, ensuring cleaner environments and reducing manual labor. It enhances hygiene and minimizes ammonia buildup.

Q: How does a manure belt cleaning system differ from traditional methods?

A: A manure belt cleaning system uses conveyor belts to continuously transport waste, improving efficiency and reducing odor. Unlike manual methods, it operates automatically and requires minimal human intervention.

Q: Can an automatic pig feeding system integrate with a manure scraper system?

A: Yes, automatic feeding and manure scraper systems can work together to streamline operations. Integration optimizes space, reduces contamination risks, and ensures synchronized farm management.

Q: What maintenance is required for a manure belt cleaning system?

A: Regular inspections of belts, motors, and sensors are essential. Cleaning debris and lubricating moving parts ensure longevity and prevent operational disruptions.

Q: What factors should be considered when installing a manure scraper system?

A: Key factors include barn size, floor design, and livestock density. Proper alignment, power supply, and compatibility with existing systems like feeding setups are also critical.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025