- 1.The floating ntses pub pellet tshuab / ntses zaub mov extruder tuaj yeem ua hom pub rau cov ntses sib txawv, xws li zaub mov ntses, ntses ntses, cws, roob ris, thiab lwm yam. cov ntses pellet ua los ntawm lub tshuab tuaj yeem ntab saum dej ntau tshaj 24 teev.

- 2. The Floating-Feed Pellet Machine can make many kinds of fodder for different kinds of animal fodder. It can make poultry-fodder, pet-fodder, as well as aquaculture-fodder and fishery feed, which is also called floating –feed.

- 3. Nws yog siv rau pretreatment ntawm cov tsiaj fodder, thiaj li yuav txo tau ntawm cov khoom noj khoom haus, ua ntej cov protein cov ntsiab lus kom cov fodder yuav zom tau yooj yim dua los ntawm cov tsiaj.

- 4. Cov nqaij qaib-khoom noj muaj peev xwm pub qaib, luav, yaj, npua, nees nyuj thiab lwm yam. Tus tsiaj-fodder tuaj yeem pub dev, miv, ntses kub thiab lwm yam. Lub Nkoj Nkoj tuaj yeem pub ntses, cws, roob ris, eel, atfish, thiab lwm yam.

|

Qauv |

Muaj peev xwm |

Main lub cev muaj zog |

Feeding chaw nres nkoj zog |

Hnub ntawm cov ntsia hlau |

Cuttingmotor |

|

YZGP40-C |

0.03-0.04 |

3.0*2 |

0.4 |

Φ40 |

0.4 |

|

YZGP40-C |

0.03-0.04 |

5.5 |

0.4 |

Φ40 |

0.4 |

|

YZGP50-C |

0.06-0.08 |

11 |

0.4 |

Φ50 |

0.4 |

|

YZGP60-C |

0.10-0.15 |

15 |

0.4 |

Φ60 |

0.4 |

|

YZGP70-B |

0.18-0.2 |

18.5 |

0.4 |

Φ70 |

0.4 |

|

YZGP80-B |

0.2-0.25 |

22 |

0.4 |

Φ80 |

0.6 |

|

YZGP 90-B |

0.30-0.35 |

37 |

0.6 |

Φ90 |

0.8 |

|

YZGP 120-B |

0.5-0.6 |

55 |

1.1 |

Φ120 |

2.2 |

|

YZGP135-B |

0.7-0.8 |

75 |

1.1 |

Φ133 |

2.2 |

|

YZGP160-B |

1-1.2 |

90 |

1.5 |

Φ155 |

3.0 |

|

YZGP200-B |

1.8-2.0 |

132 |

1.5 |

Φ195 |

3.0-4.0 |

Cov khoom no yog dab tsi?

Daim ntawv thov ntawm Extruder pellet tshuab

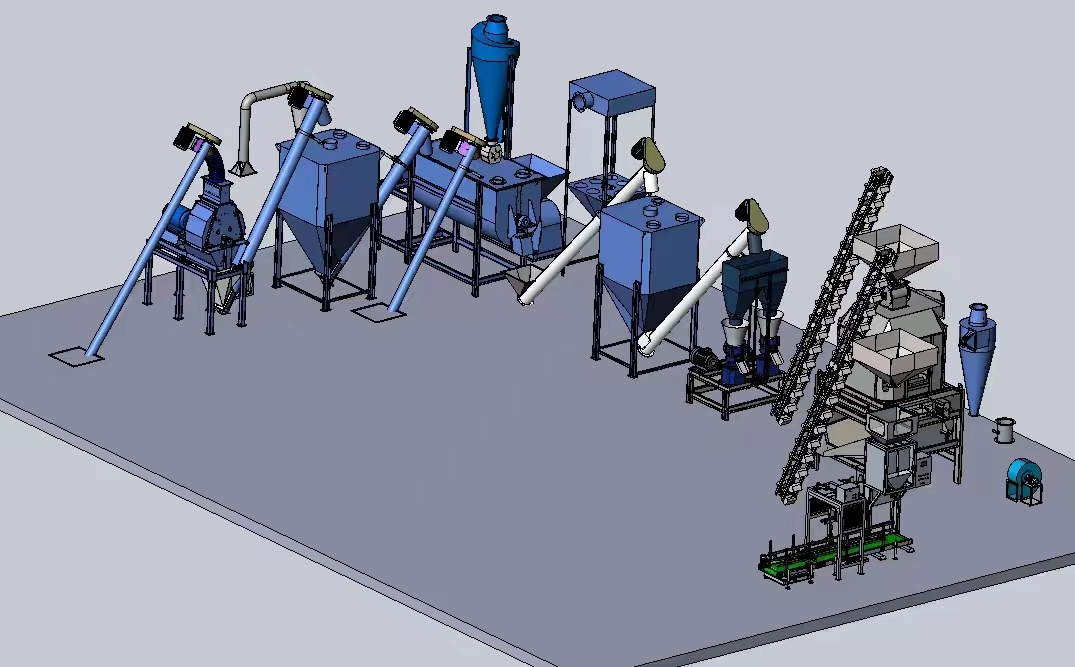

Lub tshuab extruder pellet yog dav siv nyob rau hauv kev ua liaj ua teb thiab pub kev lag luam. Nws zoo hloov cov ntaub ntawv raw, xws li nplej thiab biomass, rau hauv compressed pellets haum rau tsiaj txhu noj. Nws versatility ua rau nws yog ib qho cuab yeej tseem ceeb rau kev txhim kho cov khoom noj zoo, txo cov khib nyiab, thiab txhim kho tag nrho cov khoom noj zoo hauv kev ua liaj ua teb tsiaj.

daim ntawv thov khoom no.

How to choose Extruder pellet machine for your farm ?

Xaiv txoj cai extruder pellet tshuab rau koj cov liaj teb yuav tsum xav txog ntau yam:

Peev Xwm: Ntsuas lub tshuab pellet tso zis kom ntseeg tau tias nws ua tau raws li koj cov kev xav tau ntawm kev ua liaj ua teb.

Kev Xav Tau Lub Hwj Chim: Xyuas kom lub extruder ua raws li koj qhov muaj peev xwm siv tau thiab muaj peev xwm.

Pellet Size: Xaiv lub tshuab muaj peev xwm ua tau pellets nrog qhov xav tau loj rau koj cov tsiaj nyeg.

Material Compatibility: Paub meej tias lub extruder tsim nyog rau kev ua cov ntaub ntawv raw siv hauv koj cov liaj teb.

Durability thiab Maintenance: Xaiv lub tshuab nrog kev tsim kho thiab kev saib xyuas yooj yim kom ntseeg tau tias lub neej ntev thiab ua haujlwm zoo.

Nqi-Efficiency: Sib npaug qhov pib peev nrog cov txiaj ntsig mus sij hawm ntev thiab kev ua haujlwm tau zoo.

Hom Lub Npe: Xaiv lub chaw tsim khoom muaj koob npe nrog keeb kwm ntawm kev tsim cov tshuab extruder pellet txhim khu kev qha.

Nta: Xav txog cov yam ntxwv ntxiv xws li automation, tswj cov tshuab, thiab kev ntsuas kev nyab xeeb uas txhim kho kev siv tau thiab ua haujlwm tau zoo.

Kev Pab Txhawb Cov Neeg Siv Khoom: Tshawb xyuas cov neeg siv khoom txhawb nqa thiab kev lav phib xaub los daws cov teeb meem tam sim ntawd.

Kev tshuaj xyuas thiab Kev Qhia: Kev tshuaj xyuas kev tshawb fawb thiab nrhiav cov ntaub ntawv los ntawm lwm tus neeg ua liaj ua teb uas muaj kev paub txog cov qauv extruder tshwj xeeb uas koj tab tom xav txog.