- 1.The biomass particle air dryer has strong overload resistance, large processing capacity, low power consumption, and fast drying speed;

- 2.The operating parameters can be changed according to different material properties, so that the material can form a stable full-cut fabric curtain in the dryer cylinder, and the mass and heat exchange is more sufficient;

- 3.The feeding and discharging device is stable, which solves the problems of drum dryer feeding blockage, discontinuity, unevenness and return, and reduces the load of the dust removal system;

- 4. The internal structure is reasonable, which strengthens the cleaning and heat conduction of the dispersed materials, eliminates the sticking phenomenon on the inner wall of the cylinder, and has stronger adaptability to the moisture and viscosity of the materials.t;

|

type |

power kw |

capacity kg/h |

size mm |

|

TF 300 |

2.2+1.1 |

600 |

1900*1000*2500 |

|

TF 500 |

2.2+1.1 |

1000 |

2200*1100*1700 |

|

TF 800 |

3+1.1 |

1600 |

3000*1200*1850 |

|

TF 1000 |

5.5+1.5 |

2000 |

3500*1500*1900 |

|

TF 2000 |

5.5+3 |

4000 |

|

what is this product?

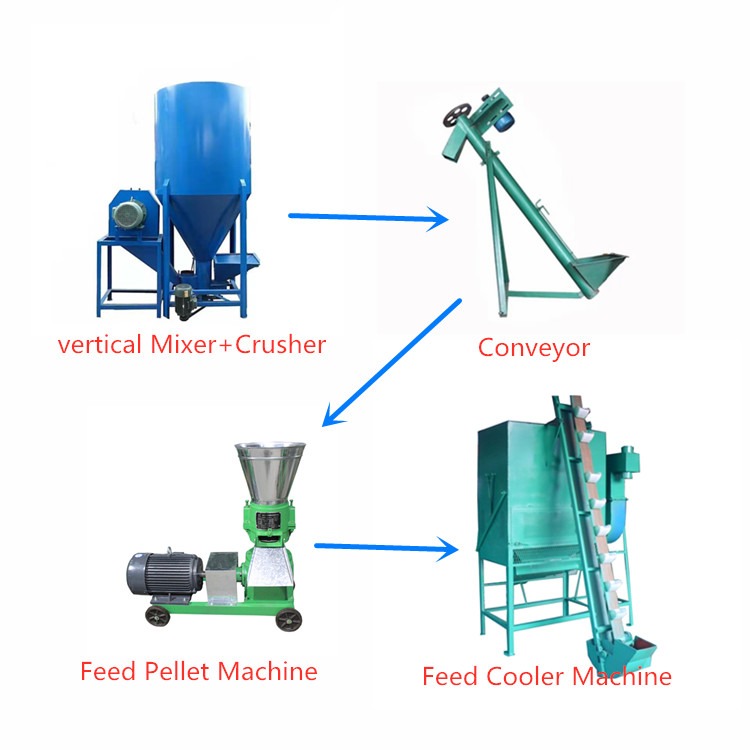

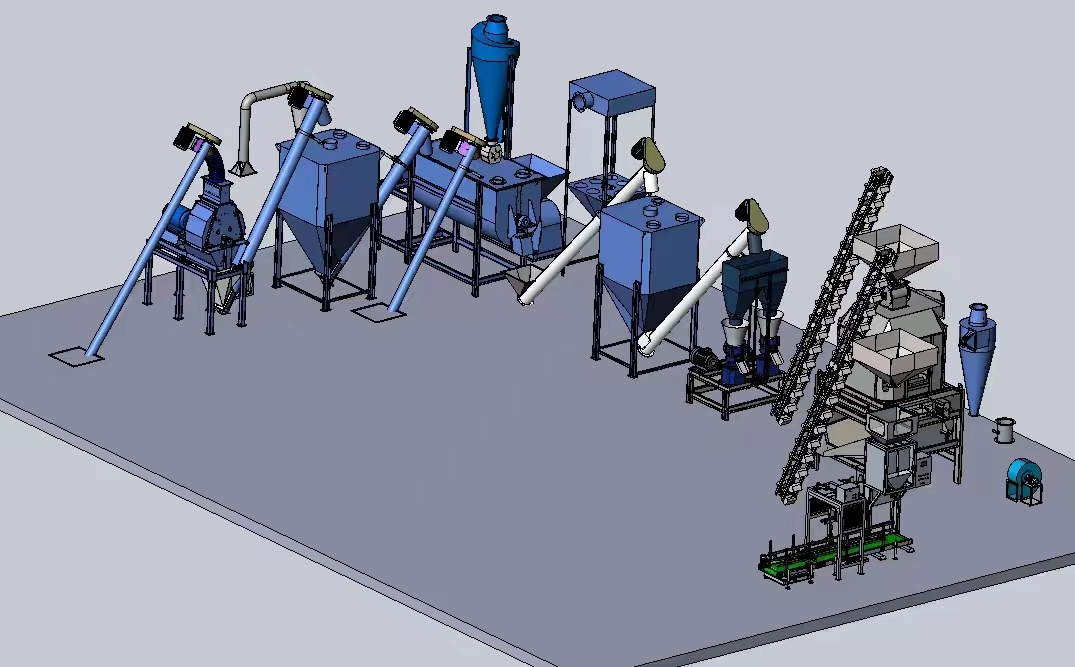

Application of feed pellet cooling machine

A feed pellet cooling machine is a vital component in the feed pellet production process. It is used to cool down hot and moist feed pellets just after they exit the pellet mill. This rapid cooling prevents pellet spoilage and maintains their structural integrity. By reducing moisture content and temperature, the cooling process ensures the feed pellets are safe for storage, packaging, and transportation. It plays a crucial role in producing high-quality, shelf-stable feed for livestock and poultry.

this product application?

How to choose feed pellet cooling machine for your farm ?

When selecting a feed pellet cooling machine for your farm, consider capacity, cooling efficiency, and design. Determine the machine's capacity to match your pellet production rate. Ensure it provides effective cooling to reduce pellet temperature and moisture content. Look for models with adjustable airflow and temperature controls for flexibility. Choose a design that fits your production line layout and space availability. Evaluate durability and ease of maintenance. Consider your budget and long-term needs when making a selection that suits your farm's requirements.