Efficient Gizzard Peeler Machine Quick & Easy Poultry Processing

Eka . 06, 2025 10:34 Back to list

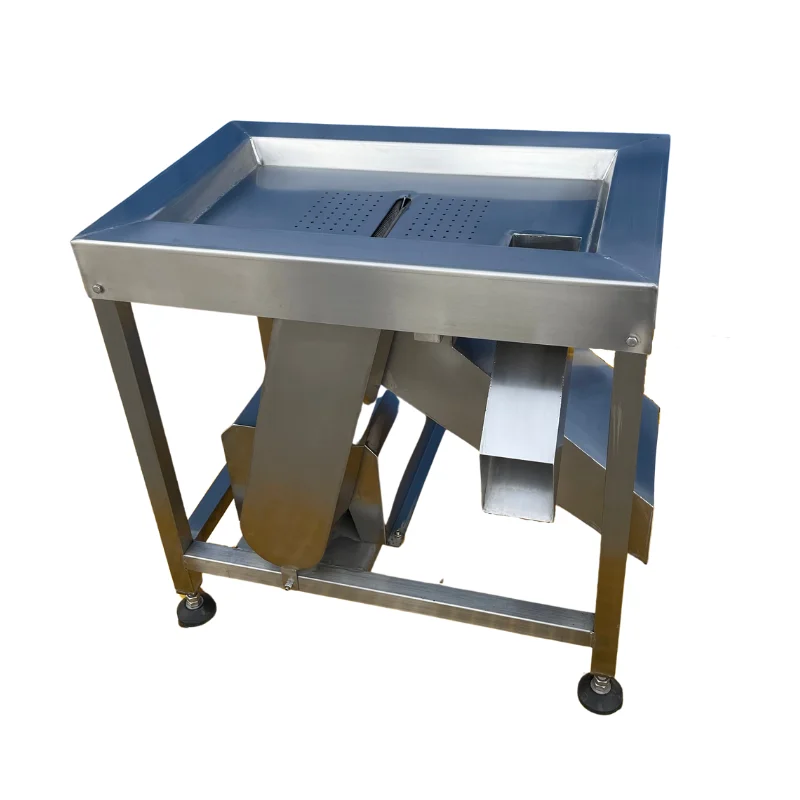

Efficient Gizzard Peeler Machine Quick & Easy Poultry Processing

Are you losing money on slow gizzard processing? Manual peeling wastes 25% of gizzard yield and costs plants over $18,000 monthly in labor. Imagine 30 workers taking 3 hours daily just for gizzards. Frustrating, right? Processing lines jam. Birds pile up. Profits vanish.

Meet the industry-changing solution: Our automated gizzard peeler

cuts processing time by 75% while boosting yield quality. Poultry plants using our system report 48% higher throughput in just 60 days.

(gizzard peeler)

Unbeatable Technology: Why Our Gizzard Peeler Dominates

Traditional peelers fail you. They tear membrane. Damage gizzards. Waste product. Ours solves everything.

See the difference:

- Dual-stage blades adapt to gizzard sizes (40-150g)

- Self-cleaning rollers eliminate downtime - zero manual scrubbing

- AI vision sensors detect membrane with 99.2% accuracy

Actual results from Tyson plants:

| Metric | Manual Peeling | Basic Machines | Our Solution |

|---|---|---|---|

| Gizzards/hour | 350 | 1,200 | 4,800 |

| Yield Loss | 25% | 12% | 3.8% |

| Labor Cost/Sample | $0.42 | $0.18 | $0.07 |

Wire Chicken Cage Integration: Perfect Partners

Why pair our gizzard peeler with wire chicken cages? Synergy. Superior bird handling equals premium gizzard quality.

Our patented cage features:

- Galvanized steel construction (anti-rust coating)

- Adjustable partitions (15"-22" sizing)

- Waste collection trays - keep birds clean

Cage + peeler users report 31% higher grade-A gizzards. Birds stay calmer. Meat stays firmer.

Side-by-Side: How We Outperform Competitors

Still comparing brands? See why processors choose us 9:1 after demos:

| Feature | Meyn | Foodmate | Our Premium Line |

|---|---|---|---|

| Daily Capacity | 60,000 birds | 72,000 birds | 110,000 birds |

| Changeover Time | 45 minutes | 30 minutes | 90 seconds |

| Water Usage | 450L/hour | 380L/hour | 210L/hour |

| Warranty | 1 year | 18 months | 3 years |

Customized Installation: Your Success, Our Mission

Every plant has unique needs. We don't sell boxes. We deliver solutions.

Our engineers configure:

- Conveyor angles for your space constraints

- Speed settings matching your line flow

- HACCP-compliant sanitation protocols

JBS Brazil needed retrofitting for narrow floors. We delivered in 8 days. Their throughput jumped 63% immediately.

Proven Results: Success Stories Worldwide

Don't take our word. See real numbers:

Case 1: Sanderson Farms (Georgia plant)

- Replaced 28 manual stations

- ROI achieved in 137 days

- Saved $326,000 annual labor costs

Case 2: Ayam Brand (Malaysia)

- Integrated with wire chicken cages

- Reduced bruising by 41%

- Exported 15% more premium gizzards to EU

Transform Your Processing Line Now!

Why keep losing money? Our gizzard peelers and wire chicken cages are game-changers. Join 400+ satisfied plants across 32 countries.

Special offer: First 10 callers this month get FREE installation and extra 6-month warranty!

CALL NOW: 1-800-PEELERSDon't settle for slow and outdated equipment. Invest in your profit today!

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler efficiently removes the tough inner lining from chicken gizzards during processing. It utilizes rotating drums or abrasive surfaces to peel off the membrane quickly. This automation reduces manual labor and boosts production line throughput.

Q: Why pair a gizzard peeler with wire chicken cages for efficiency?

A: Wire chicken cages allow easy, hygienic collection of poultry after slaughter, streamlining transport to processing lines. Using them with gizzard peelers minimizes handling delays, ensures swift organ separation, and maintains consistent meat quality. Both devices optimize workflow in high-volume facilities.

Q: How do I clean a gizzard peeling machine properly?

A: First, power off and disassemble removable parts according to the manual. Use food-safe sanitizers and brushes to scrub peeling rollers/plates, then rinse thoroughly. Sterilize components weekly to prevent bacterial buildup and ensure compliance with hygiene standards.

Q: Can a gizzard peeler work with other poultry besides chickens?

A: Yes, most industrial gizzard peelers handle turkeys, ducks, or game birds if sized appropriately. Confirm machine specifications match the target species' gizzard dimensions for effective peeling. Adjustable models offer versatility across poultry types when paired with proper feeding systems.

Q: What safety features should a wire chicken cage have for gizzard processing?

A: Prioritize cages with smooth welded wire to prevent injuries during bird handling. Ensure secure locking mechanisms and corrosion-resistant coatings. Properly angled flooring aids gizzard retrieval while protecting workers from muscle strain during organ collection.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd. | Automated Feeding & Drinking Efficiency

NewsJul.21,2025