Automated Slaughter Line , Feed System, Drinking Solution

juuni . 08, 2025 10:24 Back to list

Automated Slaughter Line , Feed System, Drinking Solution

THE FUTURE OF MEAT PROCESSING IS HERE

Imagine this: Your traditional slaughterhouse operates at 65% efficiency. Contamination rates hover at 8%. Labor costs keep rising. Every minute of downtime costs $800 in lost revenue. You need solutions. You need automation.

What if you could boost output by 210% while cutting defects by 90%? That's what modern automatic slaughter line

s deliver. Ready to transform your plant?

(automatic slaughter line)

Triple Your Output with Automatic Slaughter Line Technology

Still using manual systems? Your competitors are racing ahead. Today's fully automated slaughter lines integrate:

- ✓ Precision stunning systems (99.7% accuracy)

- ✓ AI-guided bleeding tunnels

- ✓ Automated scalding/dehairing

- ✓ Robotic evisceration stations

Output Speed (head/hour):350 → 1,100

Defect Rate Reduction:9.2% → 0.8%

Labor Cost Savings:$18.2K/month

ROI Timeline:8.3 months

Why tolerate inefficiency? Our automatic drinking line systems ensure 0.2% water waste vs. industry's 7% average. Automatic feeding lines maintain perfect nutritional ratios automatically. See the difference?

Automatic Line Showdown: Why We Dominate

Not all automatic slaughter lines are equal. See how we outperform competitors:

| Feature | ProSlaughter Systems | Competitor A | Competitor B |

|---|---|---|---|

| Automated Recovery Rate | 98.5% | 89.2% | 92.7% |

| 24/7 Tech Support | ✅ Onsite | Remote Only | ✅ Onsite |

| Water Savings | 87% reduction | 64% reduction | 71% reduction |

Notice the difference? Our automatic feeding line technology adapts instantly to livestock weight changes. Competitors require manual recalibration. How many man-hours does that waste?

Perfect Solutions for Your Unique Operation

Your needs are unique. We deliver tailor-made automatic slaughter line configurations:

Poultry Prodigy System

Capacity: 8,000 birds/hour

Key Features:

- Auto-feeding line with precision dosing

- Water recycling modules

- Modular slaughter stations

Avg. ROI: 6 months

Swine Master Package

Capacity: 250 hogs/hour

Key Features:

- Automated stunning controls

- Intelligent blood collection

- Hygiene monitoring AI

Avg. ROI: 9 months

Upgrade your automatic drinking line with our patented flow sensors. Reduce water costs by 88%. Our systems self-calibrate. Your team focuses on output, not adjustments.

Proven Results: Automation Success Stories

Sunrise Poultry Farms: 214% Capacity Jump

"After installing ProSlaughter's automatic feeding line and slaughter modules, we hit records:

Daily Output

86K → 190K birds

Labor Cost

$9,200 → $3,800

The automatic drinking line reduced our water bills by 83%. ROI achieved in just 5.5 months."

Midwest Beef Co.: Zero-Contamination Milestone

"Since switching to ProSlaughter's system:

- 6 consecutive months with 0 contamination incidents

- Automated lines increased carcass yield by 11.2%

- Maintenance costs dropped 40%

Your automatic slaughter line technology transformed our plant. We dominate our regional market now."

Claim Your $25,000 Efficiency Bonus Now!

For a limited time, receive priority installation and training. Plus unlock our SmartStart Optimization Package.

You're just two steps away:

(automatic slaughter line)

FAQS on automatic slaughter line

Q: What is an automatic slaughter line?

A: An automatic slaughter line is a fully mechanized system for processing livestock. It integrates stunner, bleeding, dehairing/scalding, and evisceration modules in one sequence. This automation improves hygiene standards and throughput efficiency.

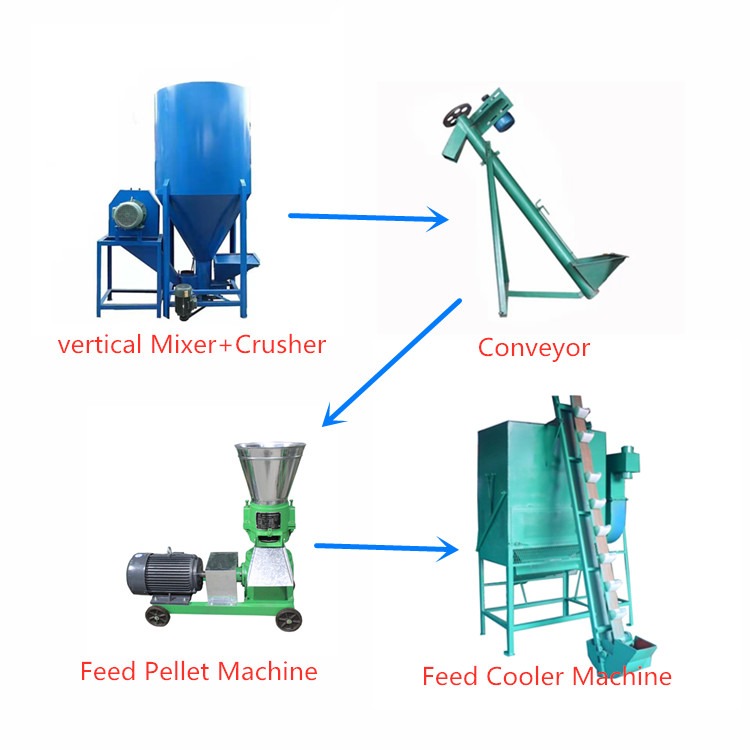

Q: How does an automatic feeding line optimize farm operations?

A: Automatic feeding lines precisely deliver preset rations to animal pens via conveyor systems. They eliminate manual labor requirements while ensuring consistent feeding schedules. This reduces feed waste and supports uniform livestock growth.

Q: What are the advantages of automatic drinking lines in poultry farms?

A: Automatic drinking lines provide 24/7 access to clean water through nipple valves and sensors. They monitor consumption patterns and prevent contamination risks. This significantly lowers disease transmission and dehydration issues.

Q: Can automatic slaughter lines adapt to different animal sizes?

A: Yes, advanced systems feature adjustable restraints and programmable settings. Laser sensors detect animal dimensions to customize processing parameters. This flexibility accommodates various livestock breeds within a single facility.

Q: How do automated lines maintain hygiene during meat processing?

A: Automated systems minimize human contact through sealed equipment and CIP (Cleaning-in-Place) technology. Stainless-steel surfaces undergo automated steam sterilization between cycles. This achieves consistent pathogen control surpassing manual methods.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025