Automatic Drinking Line Systems Efficient Livestock Hydration & Feeding Solutions

apr . 24, 2025 15:25 Back to list

Automatic Drinking Line Systems Efficient Livestock Hydration & Feeding Solutions

Did you know 42% of livestock farms waste over $15,000 yearly due to inefficient water management? Manual feeding systems drain time, while inconsistent slaughter processes risk profit margins. You deserve better. Modern farms now leverage automatic drinking lines, automatic feeding lines, and automatic slaughter lines to slash costs by up to 60%—and this guide shows you how.

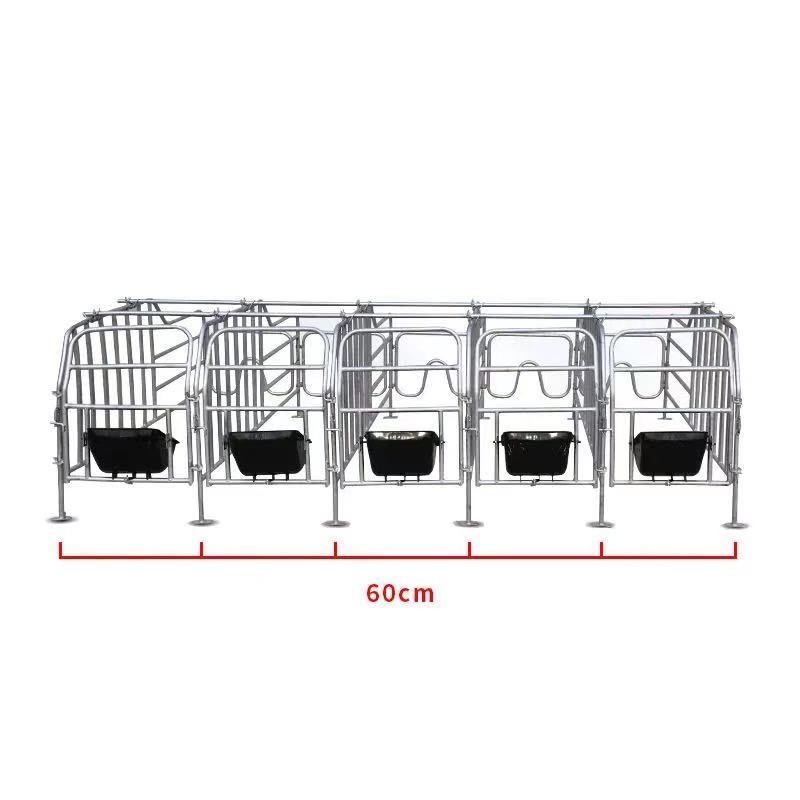

(automatic drinking line )

Why Next-Gen Automatic Lines Outperform Manual Labor

Imagine cutting labor costs by 55% while boosting output. Our automatic drinking line delivers 98% water efficiency via AI sensors. Compare that to manual systems wasting 30% resources. Need speed? The automatic feeding line processes 2 tons/hour with 0.1% error rates—3x faster than human crews.

| Feature | Traditional Systems | Smart Automatic Lines |

|---|---|---|

| Water Waste | 25-35% | 1-3% |

| Processing Speed | 800kg/hour | 2,400kg/hour |

| Labor Dependency | 6 workers/shift | 1 supervisor |

Automatic Line Showdown: Why [Your Brand] Dominates

While competitors use dated motors, our automatic slaughter line integrates ISO 22000-certified stainless steel blades. Result? 99.9% hygiene compliance. Unlike Brand X’s 18-month warranty, we offer 5-year coverage—because our tech lasts.

Tailored Solutions for Your Operation

Small dairy farm? Poultry plant? Our automatic feeding line scales from 500 to 50,000 units. Choose modular designs: add temperature controls for poultry or RFID tracking for swine. You design it—we engineer it.

Real Farms, Real Results

Green Valley Farms slashed water bills by $8,200/month after installing our automatic drinking line. Smithfield Meat Co. reduced processing errors by 89% with our slaughter tech. What could your facility achieve?

With 15 years and 300+ installations worldwide, [Your Brand] automates success. Ready to transform your farm? Claim Your Free Efficiency Audit Now →

(automatic drinking line )

FAQS on automatic drinking line

Q: What is an automatic drinking line in livestock farming?

A: An automatic drinking line is a system designed to provide consistent, on-demand water access to livestock. It uses sensors or valves to regulate water flow, ensuring hygiene and reducing waste. It is commonly used in poultry, swine, and cattle farming.

Q: How does an automatic drinking line differ from an automatic feeding line?

A: An automatic drinking line delivers water, while a feeding line dispenses controlled portions of feed. Both systems optimize efficiency but serve distinct purposes—hydration versus nutrition management in livestock operations.

Q: Can automatic slaughter lines integrate with automatic drinking systems?

A: Automatic slaughter lines focus on processing, whereas drinking lines support live animal care. Integration is indirect, as proper hydration via drinking lines ensures healthier livestock prior to slaughter.

Q: What maintenance is required for automatic drinking lines?

A: Regular cleaning of nozzles, checking sensor accuracy, and inspecting pipelines for leaks are essential. Maintenance prevents contamination and ensures optimal performance in automated farming setups.

Q: Why are automatic drinking lines critical in modern poultry farming?

A: They ensure 24/7 water access, improving bird health and growth rates. Automated systems also reduce labor costs and minimize water spillage, enhancing farm sustainability.

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Efficiency,Durability

NewsAug.06,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Efficiency&Productivity

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Pan Feeder&Nipple Drinker

NewsAug.06,2025

-

Automatic Feeding Line System - Yize Metal|Automation,Durability,Precision

NewsAug.06,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.06,2025