Introducing the key selling points of our Egg Tart Maker:

Smart Automation: Enjoy hassle-free operation with advanced intelligent control, automating the entire egg tart production process from mixing to molding.

Versatility at Its Best: Our machine is designed to cater to diverse tastes and preferences, offering the flexibility to produce a variety of flavors and creative shapes of egg tarts.

Efficient Production: Experience high-speed production with cutting-edge heating and rapid cooling technologies, ensuring stability and efficiency even in large-scale manufacturing.

Precision Control: Tailor each batch to perfection by adjusting parameters such as temperature, time, and humidity, giving you precise control over the texture and taste of your egg tarts.

Hygiene First: Crafted from food-grade materials, our Egg Tart Maker prioritizes cleanliness and safety, making it easy to clean and maintain while meeting rigorous food safety standards.

Eco-Friendly Design: Contribute to sustainability with our energy-efficient practices, minimizing environmental impact without compromising on performance.

User-Friendly Interface: Whether you're a novice or an experienced operator, the intuitive user interface ensures easy and seamless operation, making egg tart production a breeze.

In summary, our Egg Tart Maker stands out with its intelligent features, versatile capabilities, efficient production, precise control, hygiene standards, eco-friendly design, and user-friendly interface, making it the ideal solution for those seeking excellence in egg tart manufacturing.

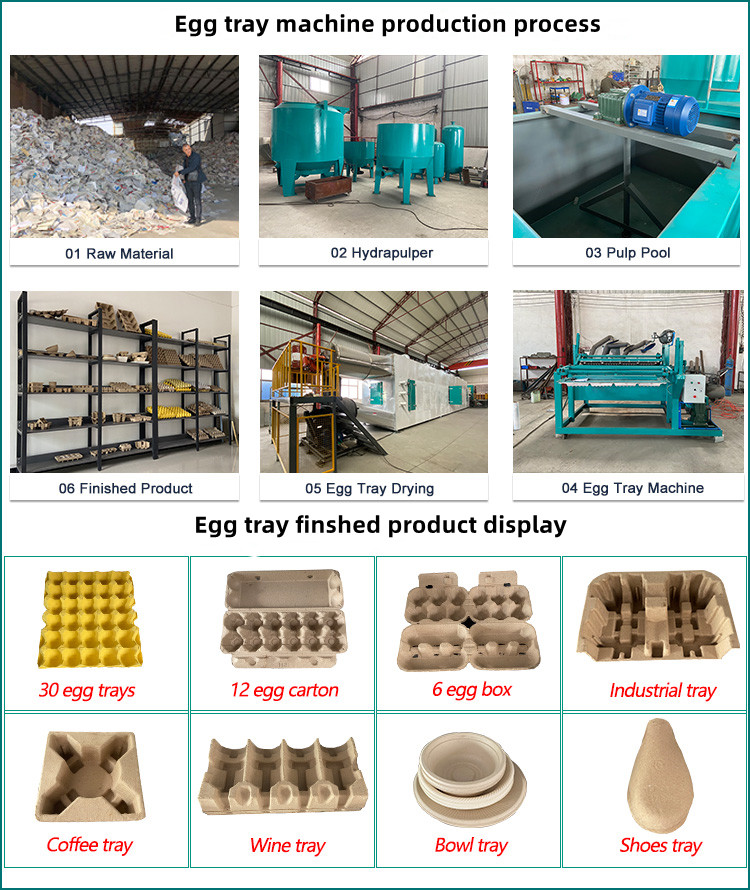

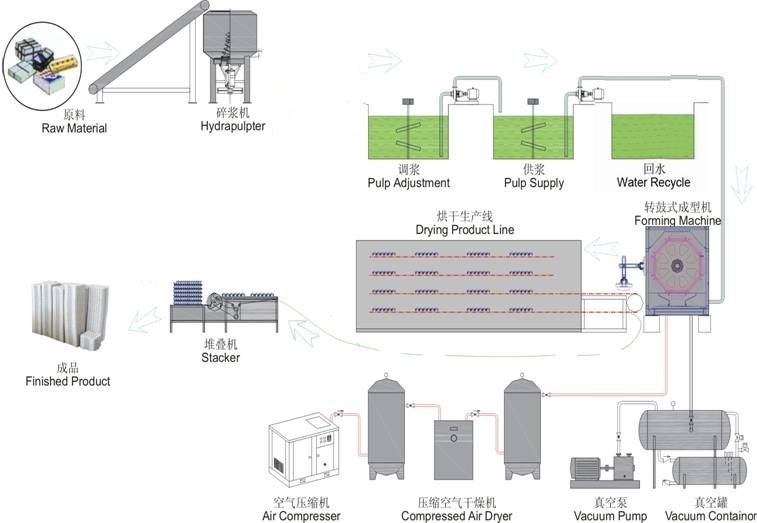

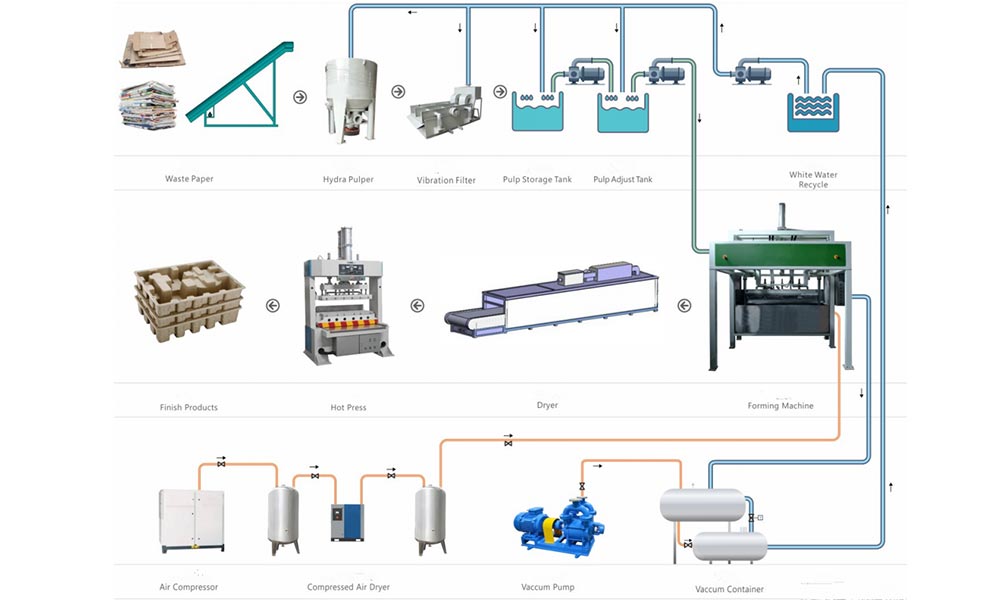

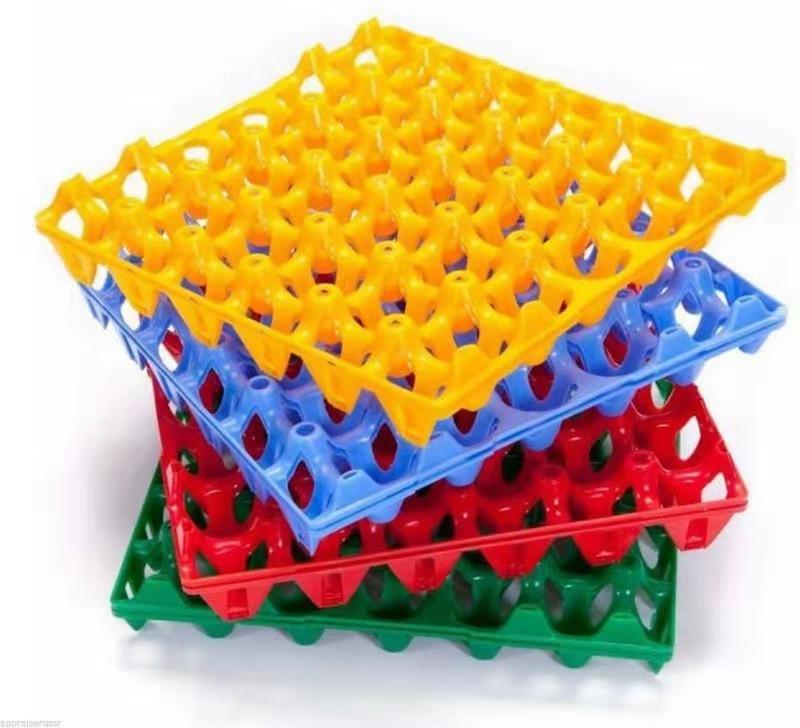

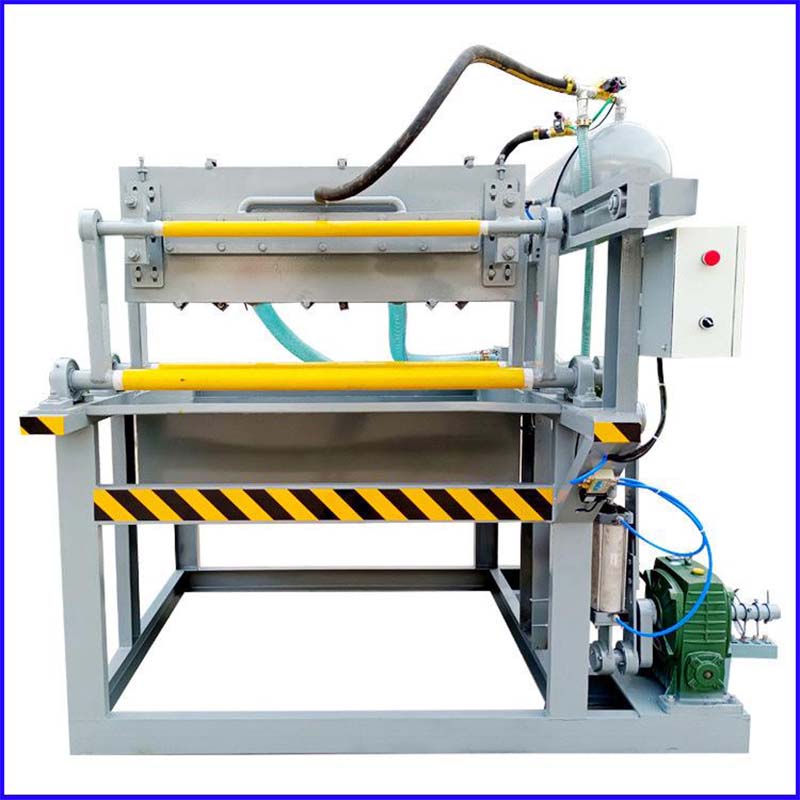

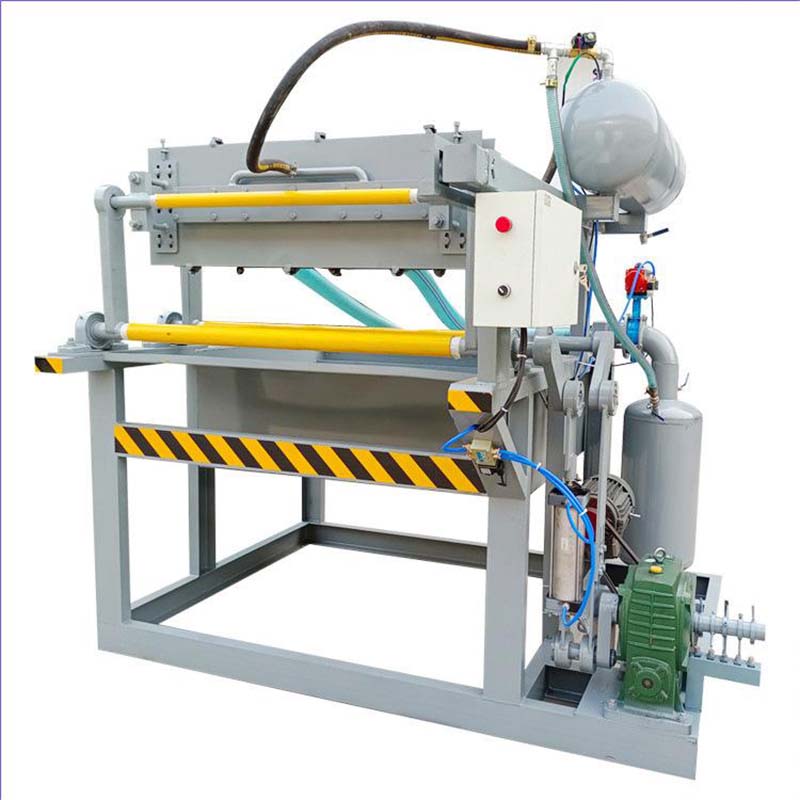

Equipment model: new version of the egg tray production line

Equipment power: 33 kW actual power consumption per hour: 20 kW

Production efficiency: 1000-1200 trays

Operator: 3-4 persons

Raw material loss: 70kg-85kg per hour

Installation cost:

Accommodation, food and drink, and customer responsibility. All expenses

for foreign installation are paid by the customer.

Equipment weight: about 2.5 tons

Distribution and transportation: 20 feet container

Note: If the price of aluminum molds or other molds should be calculated

separately

Site area: production workshop 80 square meters warehouse more than 200

square meters

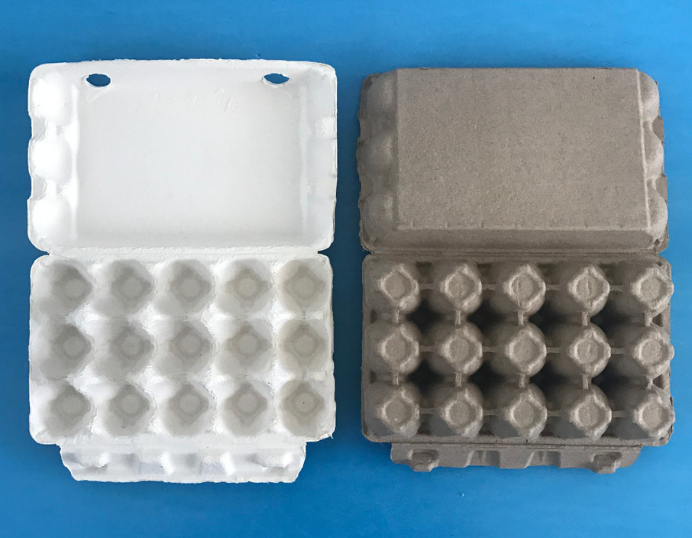

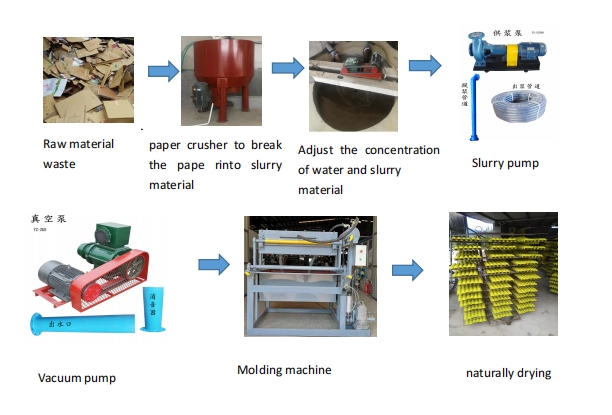

Suitable for the production of various types of egg trays, duck egg trays,

bottle trays, shoe trays, fruit trays and other pulp molding products

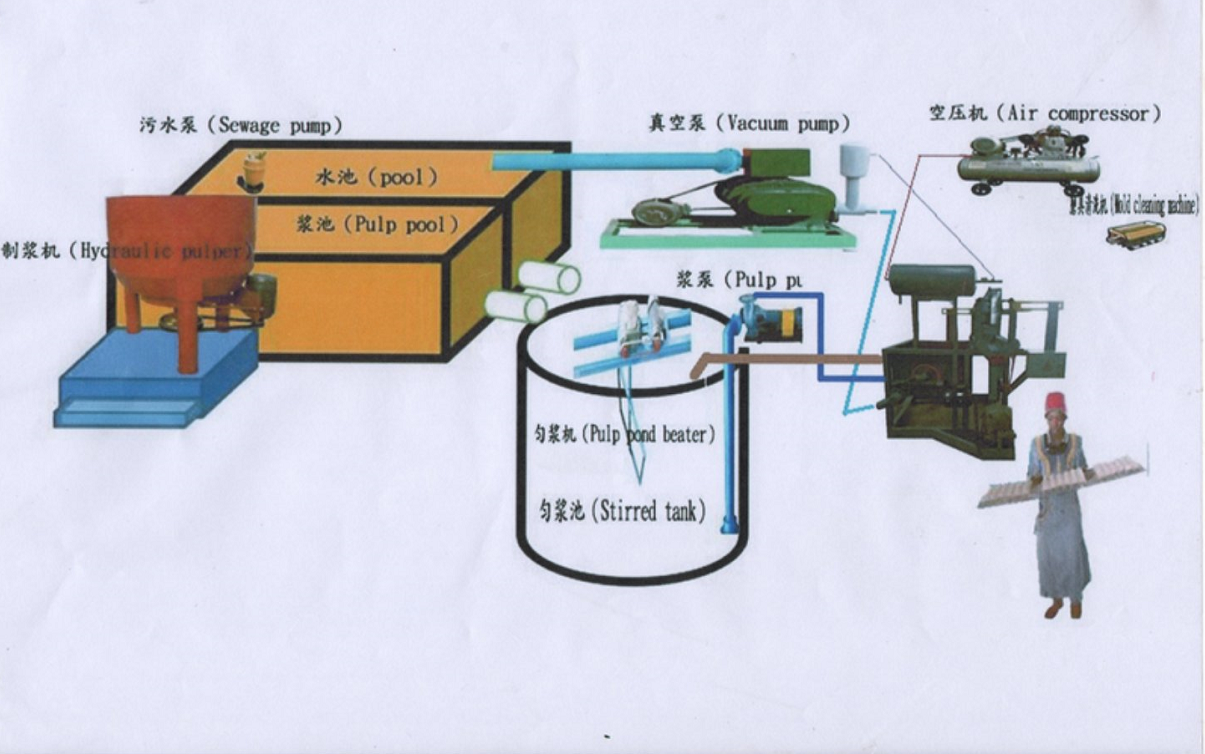

Materials and equipment need to be prepared:

(1) civil engineering materials and assistance personnel

(2) Customers need to prepare their own pool and the corresponding pipes

and valves.

(3) Cable and control switch.Install tools and welding machine.

(4) Forklift or crane

Application of Egg tray making machine

The egg tray making machine is versatile, finding applications beyond egg packaging. It produces molded pulp products for fruit, cup carriers, electronic components, seedlings, industrial items, and wine bottles. Its flexibility enables customized, sustainable packaging solutions across various industries, supporting eco-friendly practices and recycling efforts.

How to choose egg tray making machine for your business ?

Evaluate Capacity Needs: Match machine capacity with your production requirements.

Automation Level: Decide on the level of automation—fully automatic or semi-automatic.

Energy Efficiency: Opt for machines with energy-efficient features.

Mold Design Flexibility: Choose a machine allowing flexibility in mold design for diverse products.

Output Quality: Check for consistent and high-quality tray production.

Ease of Operation: Prioritize user-friendly interfaces for easy operation.

Maintenance and Durability: Consider ease of maintenance and overall machine durability.

Material Compatibility: Ensure the machine is compatible with your chosen raw materials.

Cost and ROI: Evaluate initial investment costs and projected return on investment.

Customer Support: Choose a supplier with reliable customer support and service.

Regulatory Compliance: Confirm compliance with industry and environmental regulations.