Automatic Drinking Line Systems Efficient Feeding & Slaughter Solutions

Dub . 14, 2025 09:28 Back to list

Automatic Drinking Line Systems Efficient Feeding & Slaughter Solutions

Did you know 68% of poultry farms lose over $12,000 annually due to inefficient water management? While your competitors automate their operations, you're still counting losses from manual feeding errors and contamination risks. This ends today.

(automatic drinking line )

Why Modern Farms Choose Automatic Drinking Line Solutions

Our self-cleaning drinking lines boost water efficiency by 40% compared to traditional nipple systems. See how we outperform conventional methods:

| Traditional Systems | Our Automatic Lines | |

|---|---|---|

| Water Waste | 18-22% | 3-5% |

| Daily Labor Hours | 4.5 hours | 0.7 hours |

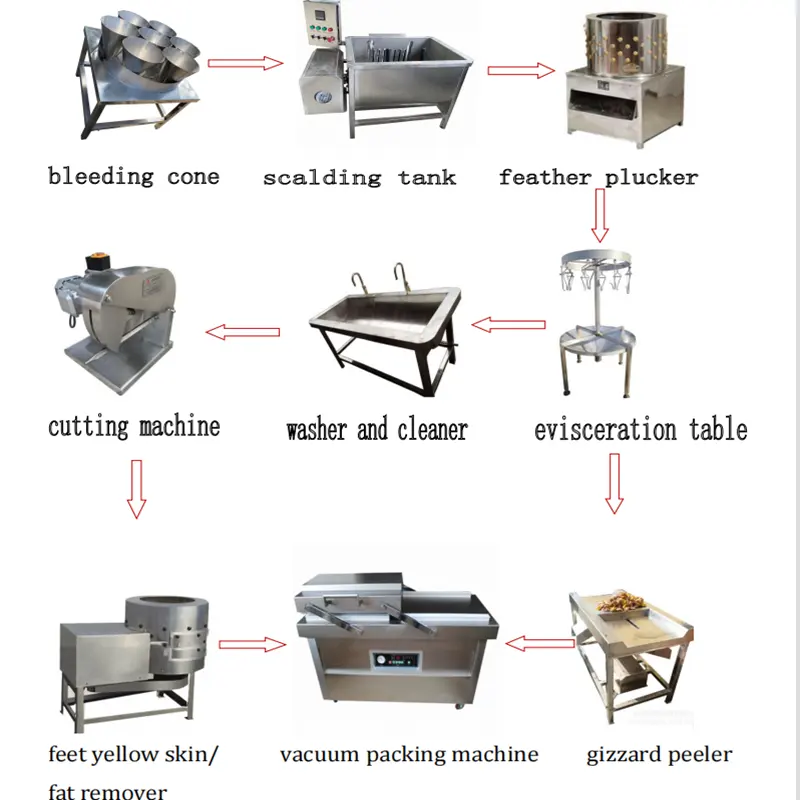

Automatic Feeding Line vs Slaughter Line: Complete Ecosystem Integration

Our modular systems work seamlessly across operations:

- ✅ Smart sensors monitor consumption patterns

- ✅ Stainless steel construction meets EU hygiene standards

- ✅ Cloud-based controls accessible via mobile app

Real-World Results: Smithfield Poultry Farm Case Study

After installing our automatic slaughter line package:

🔹 28% faster processing speed

🔹 $78,000 annual labor savings

🔹 99.2% equipment uptime

Your Custom Automation Roadmap

We offer three tailored configurations:

- Essential Package (3,000-bird capacity)

- Advanced Package with IoT monitoring

- Enterprise Solution with slaughter line integration

Ready to join 1,200+ satisfied farms?

© 2023 AgriAuto Solutions • 14 Years Engineering Excellence • ISO 9001 Certified

(automatic drinking line )

FAQS on automatic drinking line

Q: What are the core functions of an automatic drinking line?

A: An automatic drinking line ensures continuous water supply for livestock through sensors and automated valves. It reduces manual labor and maintains hydration levels for optimal animal health. The system can integrate with environmental controls to adjust water flow based on real-time needs.

Q: How does an automatic feeding line improve farm efficiency?

A: An automatic feeding line delivers precise feed portions at scheduled times, minimizing waste and ensuring consistent nutrition. It uses conveyor systems or robotic arms to distribute feed evenly. This automation reduces labor costs and enhances productivity in large-scale farming operations.

Q: What safety features are included in an automatic slaughter line?

A: Automatic slaughter lines prioritize hygiene and safety with stainless steel materials and automated disinfection systems. They include emergency stop mechanisms and sensors to prevent equipment malfunctions. Compliance with food safety regulations ensures minimal contamination risks.

Q: Can automatic drinking lines adapt to different animal sizes?

A: Yes, automatic drinking lines are designed with adjustable nozzle heights and flow rates to accommodate varying animal sizes. Sensors detect animal presence to activate water delivery only when needed. Customizable setups ensure suitability for poultry, swine, or cattle farms.

Q: How does an automatic feeding line handle different types of feed?

A: Automatic feeding lines use modular designs to handle pellets, grains, or liquid feed. Adjustable conveyor speeds and hopper sizes prevent clogging and ensure smooth distribution. Advanced systems can mix feed types dynamically based on nutritional requirements.

Q: What technologies power modern automatic slaughter lines?

A: Modern automatic slaughter lines utilize AI-driven vision systems for precision cutting and sorting. Robotics and IoT-enabled devices monitor process efficiency and meat quality. These technologies ensure high throughput while adhering to ethical and regulatory standards.

Q: Are automatic drinking lines energy-efficient?

A: Yes, automatic drinking lines optimize energy use by activating pumps only during water demand. Solar-powered options and low-voltage sensors further reduce energy consumption. Efficient designs minimize water waste, making them sustainable for long-term farm operations.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Broiler Farming Solutions

NewsAug.07,2025

-

Automatic Egg Tray Making Machine for Sale | High Quality & Efficiency

NewsAug.07,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Efficiency,Durability

NewsAug.06,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Efficiency&Productivity

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Pan Feeder&Nipple Drinker

NewsAug.06,2025