chicken feet processing machine

Dec . 16, 2024 11:09 Back to list

chicken feet processing machine

The Rise of Chicken Feet Processing Machines Innovations in Poultry Industry

In recent years, chicken feet have emerged as a delicacy in many cultures, particularly in Asian countries where they are revered for their unique texture and flavor. The increasing international demand for chicken feet, coupled with the growing interest in sustainable food production, has led to a significant shift in poultry processing methods. Central to this transformation is the development and refinement of chicken feet processing machines. These machines not only enhance productivity but also ensure that the processing adheres to health and safety standards.

Understanding the Chicken Feet Processing Machine

Chicken feet processing machines are specialized equipment designed to automate and streamline the various stages of cleaning, peeling, and packaging chicken feet. The traditional method of processing chicken feet involves a labor-intensive and time-consuming approach, which can often lead to inconsistencies in quality. However, modern machines integrate multiple functions into one compact unit, drastically improving efficiency and hygiene.

The key components of a chicken feet processing machine typically include a scalder, a peeling device, a cleaning system, and a packing station. The scalder uses hot water to loosen the skin, making it easier to peel. Following this, the peeling machine removes the outer layer swiftly and effectively, ensuring minimal waste. The cleaning system further sanitizes the feet, removing any residual contaminants, and finally, the packed chicken feet are ready for shipment or further processing.

Advantages of Automated Processing

1. Efficiency One of the main advantages of using chicken feet processing machines is the remarkable increase in processing speed. Manual labor may take hours to process a batch, while machines can accomplish the same task in a fraction of the time. This efficiency is crucial in meeting growing consumer demand.

2. Consistency With machines, each piece of chicken feet is processed uniformly, resulting in consistent quality and size. Consumers and businesses alike prefer products that look and feel the same, and automated processes eliminate the discrepancies often found in manual work.

chicken feet processing machine

3. Hygiene Food safety is paramount, particularly in the poultry industry where contamination can lead to serious health risks. Automated processing machines are designed with hygiene protocols in mind, reducing human contact with the product and utilizing stainless steel surfaces and non-toxic materials which can withstand rigorous cleaning processes.

4. Cost Reduction While the initial investment in chicken feet processing machines might seem high, the long-term savings on labor costs and the reduction of waste can lead to significant financial benefits. By increasing productivity and ensuring the efficient use of resources, companies can see a favorable return on investment.

5. Adaptability Many modern chicken feet processing machines can be customized to suit specific production needs. Companies can choose machines that handle varying processing capacities, allowing them to scale operations as demand fluctuates.

The Future of Chicken Feet Processing

The demand for chicken feet is projected to grow, particularly as more consumers in Western countries begin to explore global cuisines. As this trend continues, the poultry industry will undoubtedly adapt by investing in more advanced processing technologies. The development of smart processing machines equipped with IoT (Internet of Things) technology could allow for real-time monitoring and adjustments, enhancing efficiency even further.

Moreover, sustainability is becoming a focal point in food production. As businesses shift towards more environmentally friendly practices, chicken feet processing machines are likely to evolve to minimize waste and energy consumption. Innovations such as water recycling systems and energy-efficient motors could become standard features, making processing not only more efficient but also eco-friendly.

Conclusion

Chicken feet processing machines are revolutionizing the way this undervalued part of the chicken is processed, offering numerous benefits over traditional methods. As technology continues to advance and consumer tastes evolve, these machines will play a crucial role in the poultry industry, ensuring that chicken feet are not only a staple in various cuisines but also a profitable product for producers worldwide. The future of chicken feet processing looks promising, paved by innovation, efficiency, and a commitment to sustainability.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

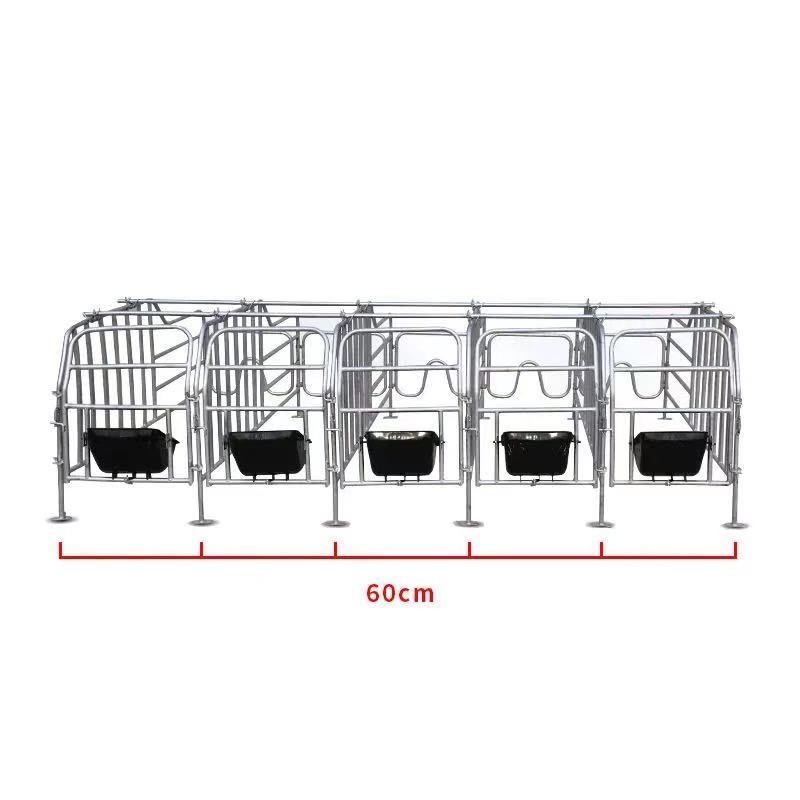

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025