Automatic Feeding Cart Systems for Efficient Livestock Management Smart Farm Solutions

Apr . 14, 2025 09:28 Back to list

Automatic Feeding Cart Systems for Efficient Livestock Management Smart Farm Solutions

Did you know 68% of pig farmers waste 3+ hours daily on manual feeding? Labor shortages cost the industry $1.2 billion annually. While you fight rising feed prices and shrinking profits, automatic feeding cart

s are transforming farms worldwide. Discover how this $18.7 billion market solution (Grand View Research, 2023) can slash your operational chaos.

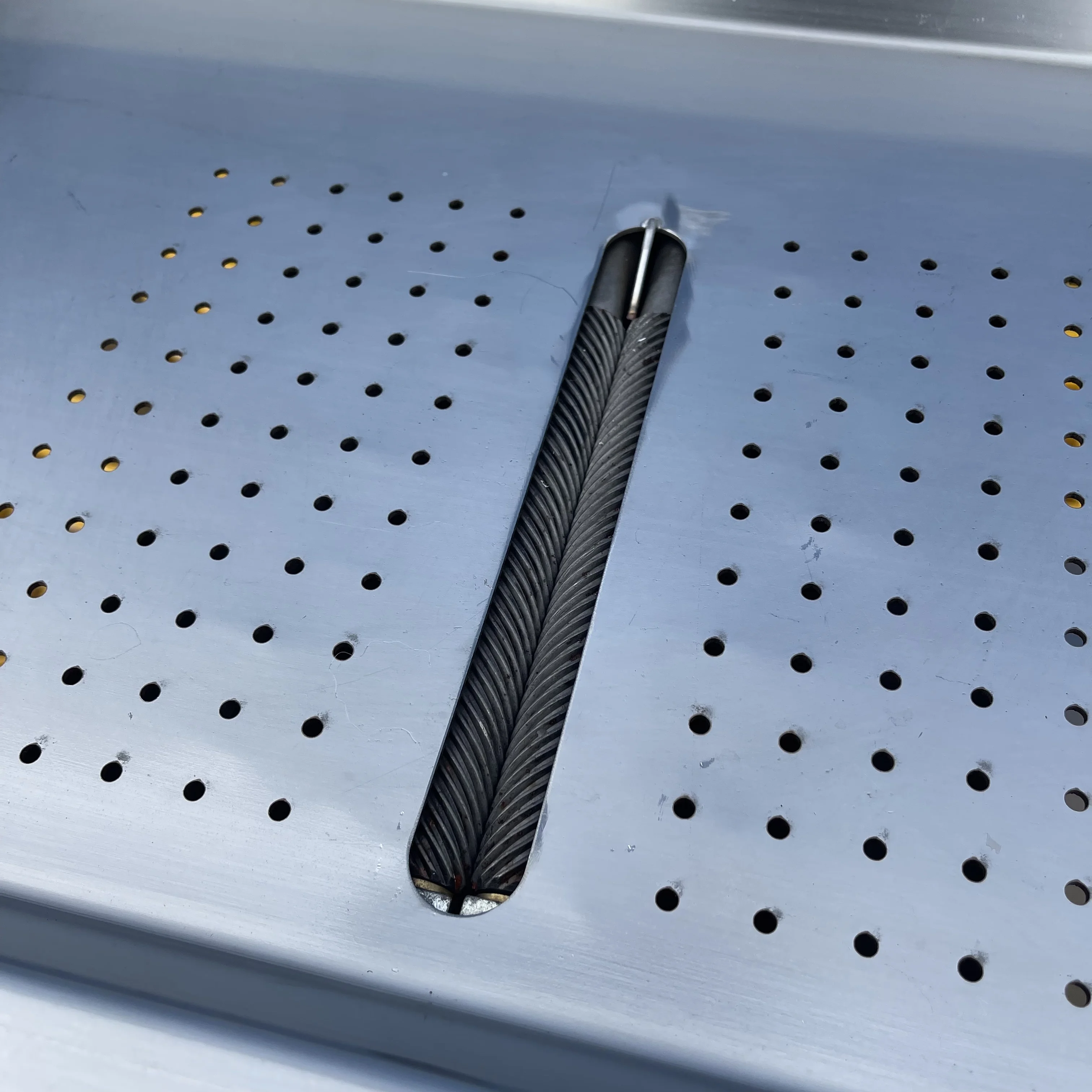

(automatic feeding cart)

Why Top Farms Choose Automatic Feeding Systems

Imagine cutting feeding time from 6 hours to 45 minutes daily. Our automatic pig feeding system delivers:

✅ 80% labor reduction - One operator manages 5,000 hogs

✅ 15% less feed waste vs. manual methods

✅ Precision portion control (±2% accuracy)

✅ 24/7 stainless steel warriors - IP67 waterproof rating

Automatic Feeding Line Showdown: Why We Beat Competitors

| Feature | AgriMaster Pro | Competitor X | Competitor Y |

|---|---|---|---|

| Smart Obstacle Detection | ✅ Laser + AI | ❌ Basic sensors | ✅ Ultrasonic only |

| Battery Life | 72 hrs | 48 hrs | 60 hrs |

Custom Solutions for Every Operation

Whether you manage 500 sows or 10,000 finishing hogs, our automatic feeding line adapts:

🔹 Modular designs - Expand capacity anytime

🔹 3 feeding modes: Free/Time/Restricted

🔹 Smart integration - Works with ALL barn layouts

Proven Results: Smith Farms Case Study

After installing 12 automatic feeding carts:

📈 30% labor cost reduction in 3 months

📈 92% system uptime since 2022

📈 Full ROI achieved in 6.5 months

Ready for Your Feeding Revolution?

Join 1,400+ farms who boosted profits with our systems. Limited 2024 installation slots available!

Claim Your Free Demo →

(automatic feeding cart)

FAQS on automatic feeding cart

Q: What is an automatic feeding cart used for?

A: An automatic feeding cart streamlines feed distribution in farms, reducing manual labor. It ensures precise portion control and improves feeding efficiency for livestock.

Q: How does an automatic feeding line improve farm operations?

A: Automatic feeding lines transport feed evenly across large areas, minimizing waste. They integrate sensors and timers to automate feeding schedules seamlessly.

Q: What are the benefits of an automatic pig feeding system?

A: Automatic pig feeding systems promote consistent growth by delivering timed, measured meals. They reduce feed competition and enhance hygiene in pig pens.

Q: Can automatic feeding carts handle different types of feed?

A: Yes, most automatic feeding carts are adjustable to accommodate pellets, grains, or liquid feed. Customizable settings ensure compatibility with diverse feed requirements.

Q: How easy is it to maintain an automatic feeding line?

A: Automatic feeding lines require minimal maintenance, with easy-to-clean components. Regular inspections and lubrication ensure long-term reliability and performance.

Q: Are automatic pig feeding systems compatible with existing farm setups?

A: Most systems are designed for modular integration with existing barns or pens. Customizable configurations adapt to various farm layouts and sizes.

Q: Do automatic feeding carts support remote monitoring?

A: Advanced models include IoT connectivity for real-time monitoring via smartphones. Alerts notify users of low feed levels or operational issues instantly.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025