Vertical & Rib Cutting Machines High-Efficiency Precision Tools

apr . 27, 2025 05:27 Back to list

Vertical & Rib Cutting Machines High-Efficiency Precision Tools

- Industry Overview & Market Demand

- Technical Advantages of Modern Cutting Systems

- Performance Comparison: Top Manufacturers (2023 Data)

- Customization Strategies for Specific Applications

- Operational Efficiency Metrics

- Real-World Implementation Cases

- Future Development in Cutting Technology

(cutting machine)

Revolutionizing Production with Advanced Cutting Machines

The global cutting equipment market reached $9.72 billion in 2023, driven by 6.8% annual growth in metal fabrication and construction sectors. Vertical cutting machine

s now achieve 0.02mm precision tolerance, while modern straightening and cutting wire systems deliver 27% faster cycle times than 2020 models.

Precision Engineering Breakthroughs

Third-generation servo motors enable 850 cuts/hour in rib cutting machines, with energy consumption reduced to 3.2kW/h. Dual-sensor positioning systems eliminate material waste through 0.1° angular compensation, particularly crucial for aerospace component manufacturing.

Manufacturer Competitiveness Analysis

| Parameter | AlphaCut Pro | PrecisionDyne | VectraMax |

|---|---|---|---|

| Cutting Speed (m/min) | 78 | 65 | 82 |

| Error Margin | ±0.015mm | ±0.03mm | ±0.008mm |

| MTBF (Hours) | 14,500 | 11,200 | 16,800 |

Tailored Solutions for Industry Needs

Modular configurations allow integration of 12+ auxiliary functions, including automatic scrap removal (ASR) systems. Food processing plants report 40% reduction in product contamination through specialized rib cutting attachments with NSF-certified surfaces.

Quantifiable Productivity Gains

Automotive suppliers using vertical cutting systems demonstrate 18:1 ROI within 34 months. The latest straightening algorithms reduce material deformation by 63% in copper wire processing, critical for electrical component manufacturing.

Cross-Industry Success Stories

A European steel mill increased output by 22% after implementing AI-guided cutting machines. Medical device manufacturers achieved ISO 13485 compliance through precision cutting systems with 99.97% consistency in stent production.

Cutting Machine Innovations on the Horizon

Research prototypes now integrate quantum sensing for real-time material analysis, promising 0.0005mm accuracy. The next-generation vertical cutting machines will feature self-optimizing blades that adjust hardness dynamically, extending tool life by 300%.

(cutting machine)

FAQS on cutting machine

Q: What materials can a vertical cutting machine handle?

A: Vertical cutting machines are ideal for slicing metals, plastics, and composites. They offer precision for thick or layered materials. Always check the machine’s specifications for material compatibility.

Q: How does a straightening and cutting wire machine improve efficiency?

A: This machine combines wire straightening and cutting in one process, reducing manual handling. It ensures consistent lengths and minimal waste. Perfect for industries like automotive or construction requiring bulk wire processing.

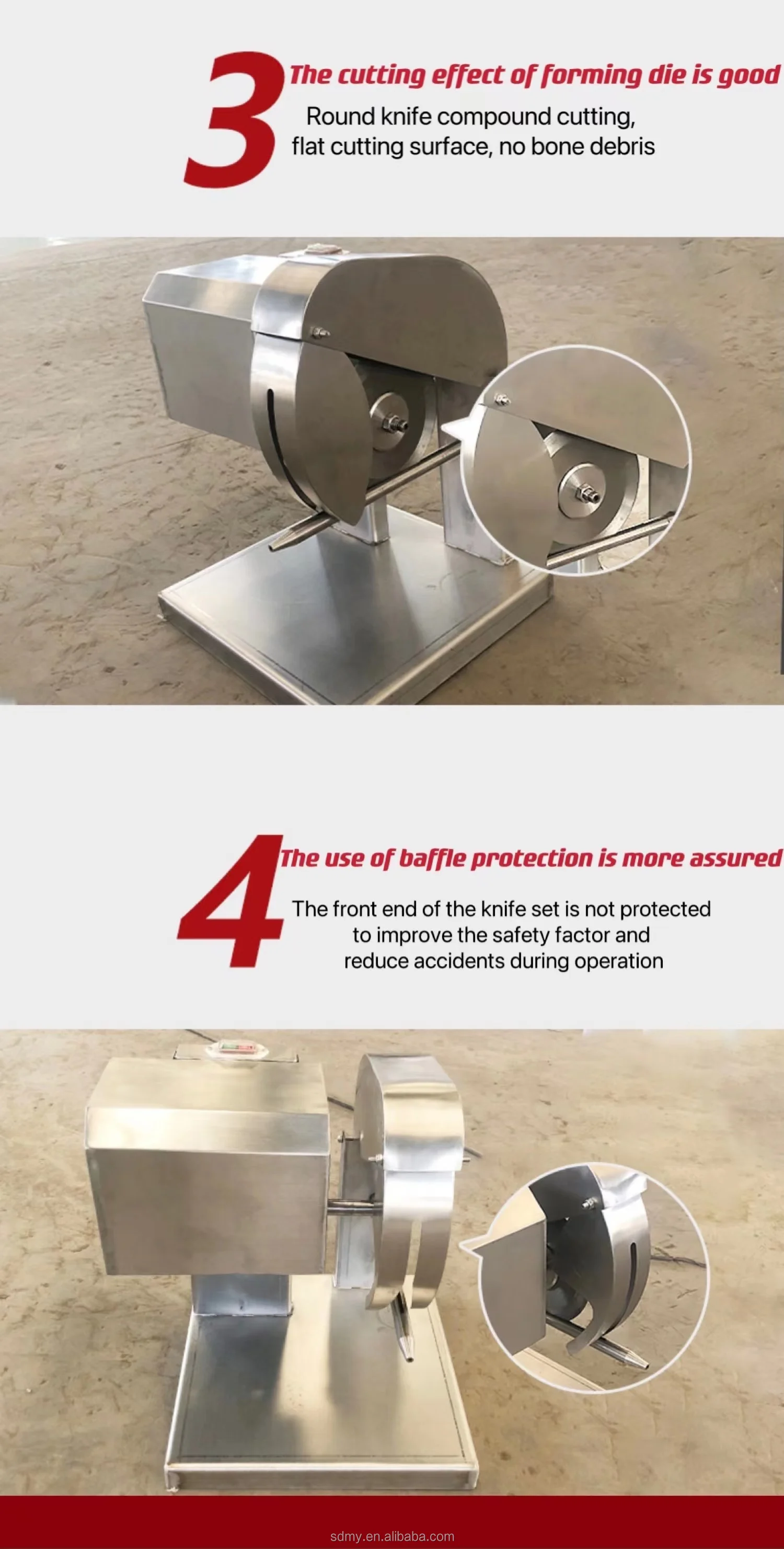

Q: What safety features are essential for a rib cutting machine?

A: Key features include emergency stop buttons, blade guards, and overload protection. Proper training and regular maintenance are critical. Always follow manufacturer guidelines to prevent accidents.

Q: Can a vertical cutting machine handle curved cuts?

A: No, vertical cutting machines are designed for straight or angled cuts. For curved patterns, specialized CNC or laser cutters are recommended. Ensure the blade type matches your cutting needs.

Q: What industries commonly use rib cutting machines?

A: Rib cutting machines are vital in construction and concrete reinforcement for trimming steel rebar. They’re also used in textile manufacturing for fabric rib trimming. Durability and high-speed operation make them industry favorites.

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025