- Surface treatment:

- Electro galvanize :

1. Surface smooth,and bright, zinc coating:20-30g/m2.

2. In the humid environment,it is easy to rust, But after the rust does not affect use, service life:8-10 years)Because this type is economic, so most people in use.

- Hot galvanize :

- 1. Surface zinc is thick but not smooth, can reach about 400-500g/m2.

- 2. the wire can last long time without rust. service life: 25 years--Even for a longer time, price is the most expensive one.

PVC coated after electric galvanized :1.Surface smooth and bright, Green Color pvc coated outside, inside is electro galvanized wire.2.Because this is two layers of surface treatment,corrosive protection performance is much more better, service life:more than 20 years.

|

Item |

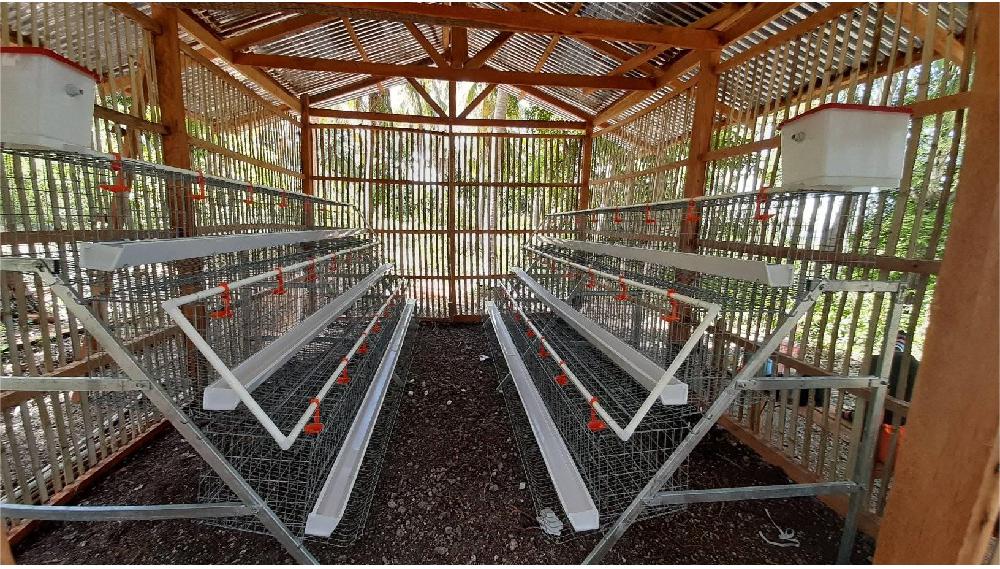

H type Broiler Chicken Cage |

|

Tiers |

3/4 Tiers |

|

Size |

1200*1400*400/600 (BH3) |

|

1400*1000*400/600 (BH4) |

|

|

1400*1000*400/600 (BH3) |

|

|

1400*1000*400/600 (BH4) |

|

|

Material |

Hot galvanized Q235 Steel Wire |

|

Operation Method |

Automatic Or Manual |

|

Applicable Industries |

Poultry Farms |

|

Supporing Systtem |

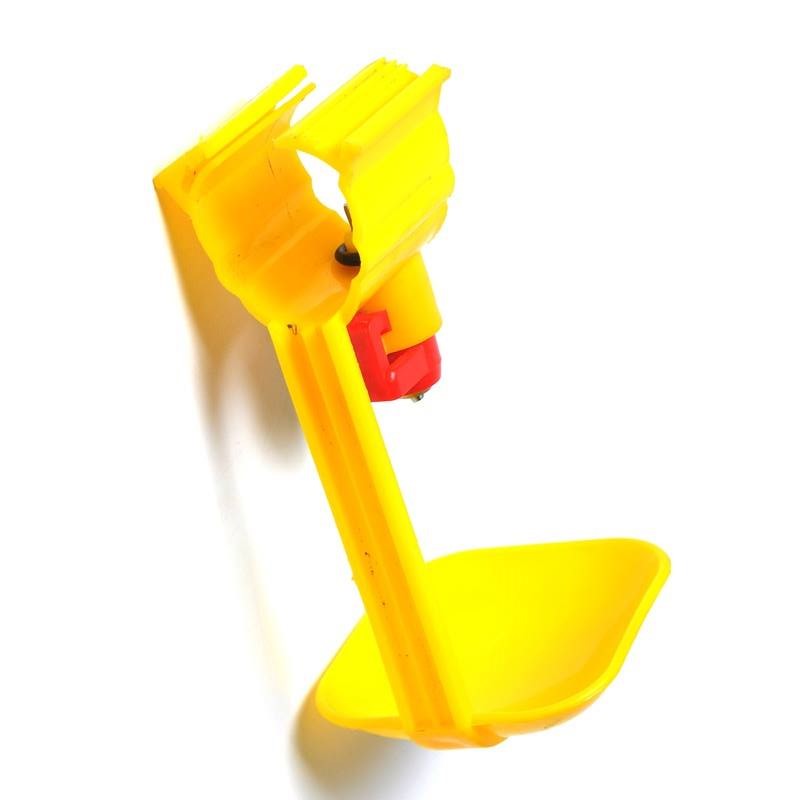

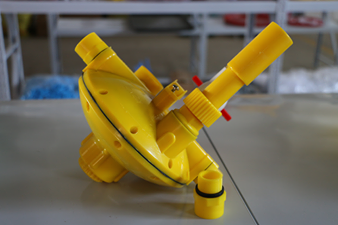

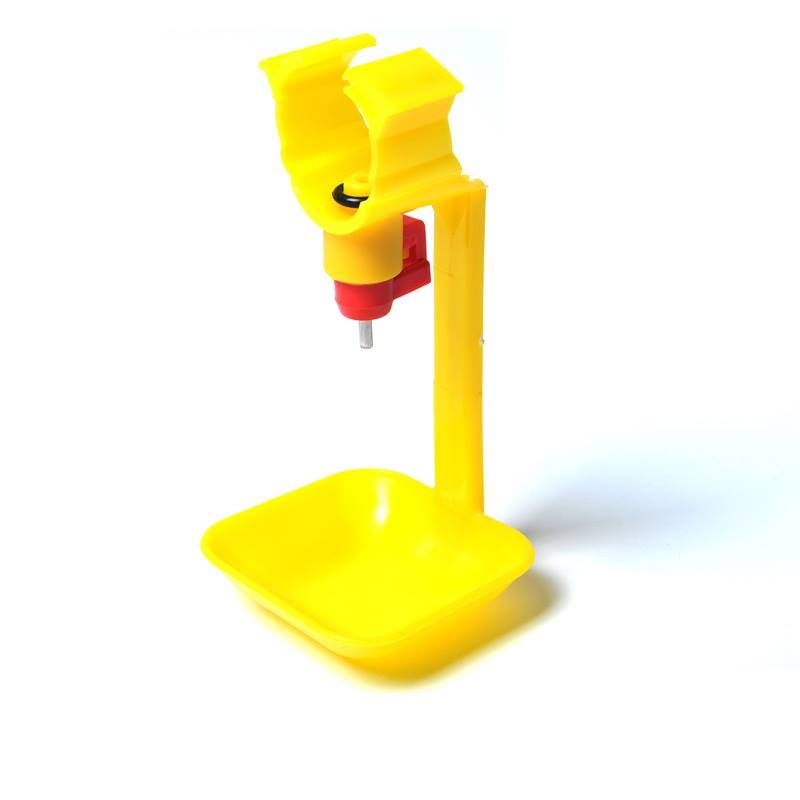

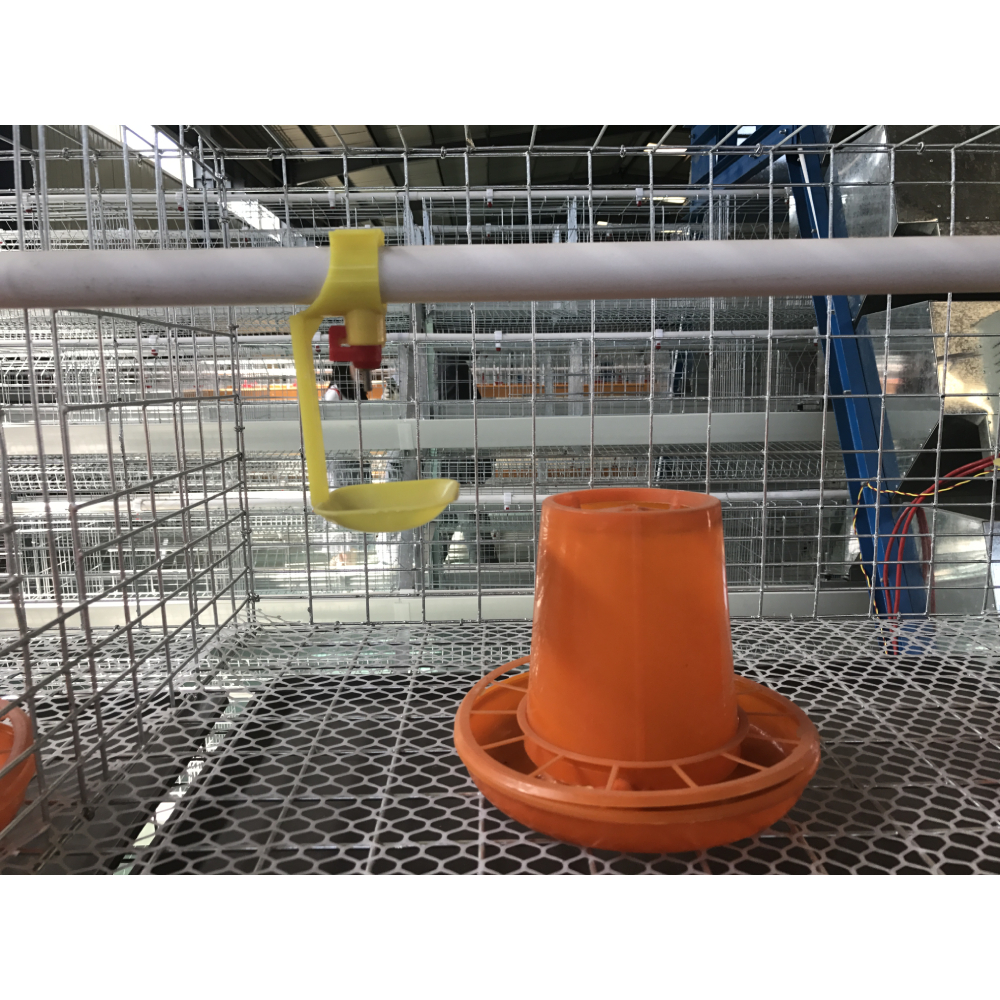

Automatic Drinking System |

|

Automatic Feeding System |

|

|

Automatic Ventilation System |

|

|

Automatic Manure Cleaning System |

what is this product?

Application of Chicken Cages

Chick cages are essential in modern poultry farming for efficient meat production. These specialized cages maximize space utilization, enhance hygiene, and aid disease control. They promote uniform growth, automate feeding, and reduce labor intensity. Broiler cages facilitate environmental control and monitoring while complying with regulations. They enable higher stocking densities, which can increase production. Careful consideration of cage type, quality, ventilation, and animal welfare ensures successful broiler rearing while balancing cost and supplier reputation. These cages are vital tools in the sustainable and ethical production of broiler chickens.

this product application.

How to choose layer cages for your poultry farm ?

Space: Calculate the available space and the number of birds you intend to raise. Ensure the cages fit comfortably within your facility.

Cage Type: Decide between battery cages (stacked) or single-tier cages based on your farm's layout and capacity.

Quality: Invest in durable, corrosion-resistant cages made of high-quality materials to ensure longevity.

Ventilation: Choose cages with adequate ventilation systems to maintain optimal air quality and temperature.

Automation: Opt for cages with automated feeding and watering systems to reduce labor and ensure uniform bird access to food and water.

Animal Welfare: Prioritize cage designs that consider bird comfort and welfare, adhering to ethical standards and regulations.

Cost: Balance quality and affordability, considering long-term returns on investment.

Supplier Reputation: Select reputable suppliers with a track record of delivering quality products and after-sales support.

Regulations: Comply with local regulations and industry standards regarding cage specifications and bird welfare.

Future Expansion: Plan for future growth by choosing modular cage systems that can be easily expanded or customized.